small grinding mill, small grinding mill Suppliers and

offers 648 small grinding mill products. About 21% of these are Flour Mill, 9% are Mine Mill, and 23% are Grinding Equipment. A wide variety of small grinding mill

WhatsApp)

WhatsApp)

offers 648 small grinding mill products. About 21% of these are Flour Mill, 9% are Mine Mill, and 23% are Grinding Equipment. A wide variety of small grinding mill

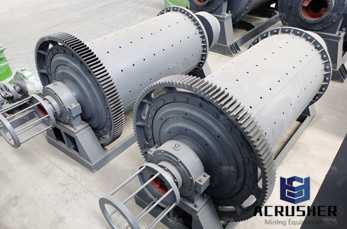

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding

#0183;#32; Ball mill grinder : Email:nina

offers 1,716 ball grinder machine products. About 15% of these are Mine Mill, 12% are Grinding Equipment, and 0% are Flour Mill. A wide variety of ball grinder machine options are available to you, such as condition, applicable industries, and warranty.

#0183;#32;Grinding a Ball Nose End Mill with the Toycen Journeyman Tool Grinder Probably the most important thing about Ball or corner radius Grinding in your position...

Table of ContentsTypes of Grinding Mill ManufacturedROD MILLSPEBBLE MILLSSelecting Wet or Dry Grinding MillHow much grinding power is neededSAG Mill vs Ball MillMill

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle, which greatly reduces the

A ball mill is a type of grinder used to grind and blend bulk material into nanosize using different sized balls. It has a Manganese Steel Lining and steel grinding media whichgrind the material into fine powder finally Grinding the tune of D9710 Microns sizes.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world. Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materials.

We provide grinding mills for laboratory use with a grinding cylinder volume of, but also industrial grinders with a grinding cylinder volume of 100L. The grinding structure of the bead mill and the material of the grinding cylinder can be customized according to the materials that the customer needs to grind, to ensure the purity of the grinding materials to the utmost extent.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

WhatsApp)

WhatsApp)