how to mill a cylinder head on a vertical mill

Cylinder head resurfacing YouTube26/03/2011 Resufracing a forklift cylinder head on my : sunppaow To Mill A Cylinder Head On A Vertical Mill s

WhatsApp)

WhatsApp)

Cylinder head resurfacing YouTube26/03/2011 Resufracing a forklift cylinder head on my : sunppaow To Mill A Cylinder Head On A Vertical Mill s

How To Mill A Cylinder Head On A Vertical Mill. How To Mill A Cylinder Head On A Vertical Mill. Jul 7, 2013 . CP Motorworks Head Fixture and a 10quot; HQT Face Mill trying a .020 cut on my 9X49. Head Stands for the Bridgeport Mill Duration: 6:48. fiatnutz 83,926 Head 201 Radius Cut Valve Job Duration: 29:58. Dec 8, 2014 .

#0183;#32;Also an 8quot; face mill on a cast iron head will need a big heavy mill with some serious horsepower. I don''t think that a face mill that big is a sensible match for a Bridgeport for example, even if you had a way to mount one on an R8 holder.

#0183;#32;How big is the cylinder? If you are milling it vertical, you can probably use a vblock to hold it, just don''t take very deep cuts. The other option is to find a Dividing Head Chuck (your shop should have one if it is at all decently stocked, whether it is large enough is another story), then you can attach it just like you would on a lathe, and rotate it to any angle that you please.

Home gt; how to clamp cylinder head to vertical mill. vertical raw mill cement industry polysius. Vertical Roller Mill repair Castolin Eutectic. In the 70s, vertical roller mills became increasingly dominant for grinding raw materials main ly for the cement industry due to their high energy efficiency.

Mill cylinder head/seat work without pilot #183; The best way and simplest way to machine seats on a vertical mill or Bridgeport is bolt/ weld some square bar stock together a rectangle box shape 2 will do. And bolt them to your rotary table standing the table straight up on one end of the table and then bolt a piece of round bar to the other side.

#0183;#32;You can buy cylinder heads with small volume chambers already cast or CNCmachined in. You can use dome pistons to effectively reduce the volume of a large combustion chamber or even choose thinner head gaskets. Or you can mill the heads. Milling involves removing material from the cylinder head

#0183;#32;First install your soft jaws and then tighten them with a piece of shim stock, say .005quot; but most any thickness will work, between the jaws. Center the spindle directly over the jaws where they clamp together and drill and ream a hole the size of the material you are trying to hold. Remove the shim stock and you are ready to go.

lock cylinder, which is a pistonoperated clamp (Head Rectangular Flange) and in vertical applications. #187; Learn More. Cylinder Heads 5 Bears Home. The fins were cut with a slitting saw on the vertical mill. Like Lee''s heads, The cylinder heads are threaded internally to match the cylinder, #187; Learn More. Flycutter Head: BHJ Products, +1 (510

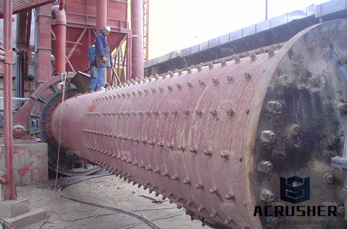

I built a cylinder head fixture for my mill to make doing cylinder head work easier. Thanks for the picture of your cylinder head fixture. With the fixture, it''s much easier to setup a head than my previous shim, parallel and clamp disaster setups. I have about 250 in materials in the fixture.

how to clamp cylinder head to vertical mill. Total Guide to CNC Milling Machine Workholding Before you can resurface or mill a cylinder head or block, you have to You can''''t just plunk a head or block onto a fixture, clamp it down and... Read More. RTM270 10_ Berco.

CPMotorworks, Inc.''s fully adjustable cylinder head fixture for knee mills. Features an allsteel construction, easy to setup and adjust. This is the most rigid fixture you will find for doing cylinder head work on your vertical mill or surfacing machine! After 5+ years of sales around the world and many different styles of heads mounted, the CPM HF2400 has proven to be the preferred setup

550 Cylinder Head Fixture Only (call to order) This Fixture Really Adds Versatility to Your Vertical Milling Machine. Provides operator with quick, rigid setups on what used to be impossible or cumbersome items. *Great for Holding Intake Manifolds *The flycutter NOW comes with a REPLACEABLE Carbide Insert Tool Holder.

Cylinder Head Tooling. Cylinder Head Fixture . Part No: CHF2 CHF, CHF2. BHJ''s Cylinder Head Fixture ensures accurate positioning of any cylinder head from an established reference point, which is necessary to properly perform many cylinder head machining operations.

Cylinder Head Tooling. Flycutter Head . Part No: FCH2 FCH, FCH2. BHJ''s Flycutter Head makes fast work of surfacing cylinder heads and blocks and adds versatility and value to your existing milling machine for all types of general machining operations.

#0183;#32;First limitation in boring cylinders in a turret mill might be the 5quot; quill stroke but if you were extend the quill and bore with the vertical knee travel (need a knee feed unit, here) you can bore to maybe 10quot; deep if the cylinder can swallow a 3 3/8quot; dia quill. It was alleged that a cylinder bored in a mill would quot;egg outquot;.

How to use a Milling Machine Instructions. Modern vertical milling machines are designed so the surface during clamping workpieces a swivel cutter head milling #187; More detailed jig borer VS vertical mill for cylinder head work. Are vertical mills(a 2hp BP clone) sturdy/accurate enough for cylinder head work, for example valve seat cutting, valve guide resizing

WhatsApp)

WhatsApp)