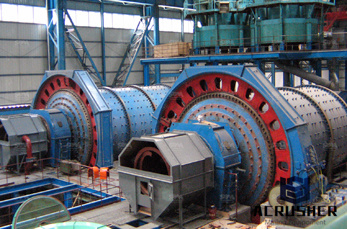

Ball mill, Grinding machine, Wet ball mill, Dry ball mill

May 22, 2014#0183;#32;Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

WhatsApp)

WhatsApp)

May 22, 2014#0183;#32;Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

offers 1,530 ball mill wet grinding products. A wide variety of ball mill wet grinding options are available to you, such as condition, local service location, and applicable industries.

Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction. These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery. Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding to analytical fineness. They are

19 #0183;#32;DOVE Ball Mills are size reduction machines, designed for grinding applications, where fine

DOVE Ball Mills are size reduction machines, designed for grinding applications, where fine material is required. Applicable for wet and dry grinding applications within the following branches of industries: Mining Construction Waste Processing Food Processing Chemical Pyrotechnics Ceramics and etc.

Jun 07, 2019#0183;#32;Wet grinding is generally used in mineral processing, because the wet ball mill has the advantages of strong materials adaptability, continuous production, large grinding ratio, easy to adjust the fineness of the milled products, and it is widely used at present.

Aug 21, 2020#0183;#32;Wet grinding is generally used in mineral processing, because the wet ball mill has the advantages of strong materials adaptability, continuous production, large grinding ratio, easy to adjust the fineness of the milled products, and it is widely used at present.

Types of ball mill: wet grinding ball mill, dry grinding ball mill, horizontal ball mill, vibration mill, large ball mill, coal mill, stone mill grinder, tumbling ball mill, etc. The ball mill barrel is filled with powder and milling media, the powder can reduce the balls falling impact, but if the power too much that may cause balls to stick

Charging a Wet Mill The general operation of a grinding mill is to have the product impacted between the balls as they tumble. Unlike dry milling, wet milling is more straight forward and more forgiving in terms of charging the product. As with dry milling there should be at least 25% liquid to fill the void space plus a bit more to insure the balls are striking product and not each other.

WhatsApp)

WhatsApp)