Steel Balls Grinding BallsWe set up technology center in

#0183;#32;Primary choice of 20 of the Fortune Global 500 enterprises We have strict quality control system to ensure that of each steel ball. sales3

WhatsApp)

WhatsApp)

#0183;#32;Primary choice of 20 of the Fortune Global 500 enterprises We have strict quality control system to ensure that of each steel ball. sales3

Grinding balls which have been used in ball mills are common grinding equipment in mineral processing and cement industries [1, 2]. Ball wear is resulted from three mechanisms namely impact

New: Silicon Carbide (SiC) Grinding Balls and Silicon Nitride (Si3N4) Grinding Balls Ball mill grinding media and milling media are used in milling or grinding processes to crush, grind and mill various materials. MSE Supplies offers a wide variety of grinding media and ball milling media with the package size ranging from kg and tons.

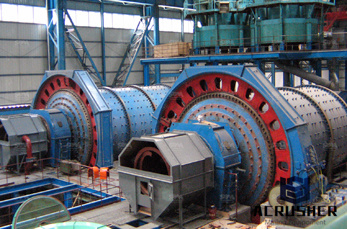

The steel ball is a material grinding medium of ball mill and coal mill. It functions as an important component of ball mill under grinding and cutting effect brought by the friction between grinding balls or grinding ball and materials.

The grinding media of the ball mill is the wearresistant grinding ball. The steel grinding ball of the ball mill is the core basic component, the grinding and stripping action happens when the steel balls crash each other or the steel balls

Steel ball is the essential grinding media of ball mill. The function of the steel ball is to grind and crush the ore stone. Steel ball is widely used in mineral processing plant, cement plant, power plant and so on. The steel ball has been developed into various shapes in many years like steel ball, steel section, steel bar

There is a scale board with steel balls in the second cabin which will grind materials. The finished powder materials are discharged from the unloading plate, thus finishing the grinding process. The ball mill is the main product made by Fote which is located in

The grinding balls fed into ball mill must be determined in accordance with the physical and mechanical properties and particle size of the ores, completely eradicating arbitrary addition. If the dimension of the steel ball added is not appropriate, it will seriously affect the grinding effect. The following are two cases often encountered in concentration plants.

Nov 11, 2014#0183;#32;The ball mill produced by Fote Machinery shows good casting process performance, high mechanical properties and good heat treatment performance to minimize the wear during materials impacting. The grinding balls are mainly made of high manganese steel: it makes ball mill balls

#0183;#32;forged steel ball, steel ball machine, steel ball grinding, milling steel balls Rita Qin. Loading anyang skew rolling machine working in Turkey to mill grinding balls Duration: 1:59.

Jun 30, 2019#0183;#32;The grinding balls fed into ball mill must be determined in accordance with the physical and mechanical properties and particle size of the ores, completely eradicating arbitrary addition. If the dimension of the steel ball added is not appropriate, it will seriously affect the grinding

Stainless Steel Balls, Carbon Steel Ball, Chrome Bearing Steel Ball for Surgical, Bearing, Grinding Mine, Machine, Nail Oil Polish, Bicycle Parts FOB Price: US / Piece Min. Order: 1 Piece

Cast Grinding Media Ball. Cast grinding media ball is widely used in mining, cement plant, power station, chemical industrial. Our grinding media ball has high chrome grinding ball,middle chrome cast grinding ball,low chrome cast grinding balls. Cast grinding ball production process There are two ways to produce grinding media ball.

Steel ball of ball mill is the material grinding media. It generates the grinding stripping by the collision between the ball and the material. Steel ball is an important basic part and plays an important role in the economic development of precision industrial. It is widely used in cement plants, power plants, etc.

WhatsApp)

WhatsApp)