white cement manufacturing process amp; Uses of white cement

Dec 02, 2020#0183;#32;White Portland cement or white ordinary Portland cement (WOPC) is similar to ordinary, gray Portland cement in all aspects except for its high degree of whit...

WhatsApp)

WhatsApp)

Dec 02, 2020#0183;#32;White Portland cement or white ordinary Portland cement (WOPC) is similar to ordinary, gray Portland cement in all aspects except for its high degree of whit...

Nov 19, 2014#0183;#32;White cement is produced via a similar process to grey cement, although the raw materials differ significantly. The iron oxide and iron sulphate content in the limestone must be as low as possible as each % increase in iron oxide reduces cement

BACKGROUND OF THE INVENTION. The conventional manufacturing process for white cement, as shown in Figure 1, involves crushing of the raw materials primarily comprising a mixture of limestone (or calcareous material) and clay, typically kaolin (or argillaceous material) in a crusher.

This 6 week online training course will be suitable for employees of white cement manufacturing companies, those who are considering manufacturing white cement, and employees of companies supplying equipment, goods and services to white cement manufacturers. Course Content. Module 1 Will cover the applications and composition of white cement

Manufacturing Process White Cement At raw mill, crushed limestone, clays and feldspar of desired chemical compositions are fed through electronic weigh... Clinkerisation is the heart of cement manufacturing process, where the raw material is fed to pre

White Cement Manufacture, Properties and Uses

1 Mixing of Raw materials in wash mill with 35 to 50% water. 2 Materials exiting the mill are called slurry and have flowability characteristics. 3 Size of the kiln needed for the manufacturing of cement is bigger. 4 Raw material can be mixed easily, so a better homogeneous material can be obtained.

White cement may be manufactured with standardized surfaceactive plasticizers or hydrophobic additives (in amounts of up to wt.%) not impairing the whiteness of the product. According to the whiteness degree, white cement is divided into three groups of the reflection coefficient: I. min. 80 %, II. min. 75 % and III. min. 68 %. The whiteness degree is

Manufacture of White Cement. The manufacturing process of white cement is same as that of grey cement, but the selection of raw material is an important part in the manufacturing process. The oxides of chromium, manganese, iron, copper, vanadium, nickel and titanium imparts the grey colour to the cement. In white cement manufacture, these raw materials are kept to least percentage.

The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement. The powdered cement is then mixed with water and aggregates to form concrete that is used in construction. Clinker quality depends on raw material composition, which has to be closely monitored to ensure the quality of the cement. Excess free lime, for example, results in undesirable effects such as volume

Aug 30, 2012#0183;#32;Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction/ Quarry. Grinding, Proportioning and Blending. Preheater Phase. Kiln Phase. Cooling and Final Grinding. Packing amp;

Apr 26, 2017#0183;#32;White cement is manufactured i n a different way as gray cement is done. Iron and manganese are supplemented in its manufacturing phase in

The invention provides a process for manufacturing white cement which includes steps of recovering flue gases generated during the quenching and drying process, extracting heat from the recovered...

In terms of type, the white cement market can be divided into white masonry cement, white Portland cement, and others. White masonry cement is mixed with masonry grade sand to produce mortar for usage in brick, block, and stone masonry construction. Portland cement is manufactured

On the basis of type, white portland cement represents the most popular product type, closely followed by white masonry cement and others. White portland cement has a high degree of whiteness which can be modified by adding mineral oxide pigments to concrete.

The production process consists of grinding the The raw materials used for the production of white cement are Lime shell, White clay, White sand and Gypsum.

and the manufacturing process. Metal oxides (iron, manganese, and others) that are present in the finished material influence its whiteness and undertone, making it imperative to use carefully selected raw materials (See Figure 1). Depending on the intended use or application, white cement can be manufactured to conform to a number

Introducing alternative fuels has an impact across the plant. The materials can have totally different characteristics from fossil fuels. They can be sticky, fluffy, moist, and fluctuating in size and quality or you may need to switch between different types of fuel with very different characteristic due to

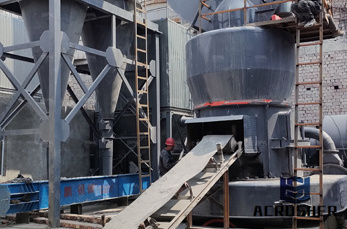

White Cement Manufacturing Process. The manufacturing process of white cement is similar to that of Portland cement. Compared with Portland cement, white cement has higher requirements for the calcining system in the cement plant. In the production process of white cement, the calcining system is the key part of the whole process, whose quality directly affects the product quality and energy

Abstract. The invention relates to a method for producing white cement, in which the reducing atmosphere is maintained over the entire length of the rotary kiln and the raw material is precalcined...

WhatsApp)

WhatsApp)