WetLimestone FGD Byproduct Generation and Limestone

Jun 01, 2010#0183;#32;WetLimestone FGD Byproduct Generation and Limestone Consumption Calculations. Issue 6 and Volume 114. By Brad Buecker, Contributing Editor.

WhatsApp)

WhatsApp)

Jun 01, 2010#0183;#32;WetLimestone FGD Byproduct Generation and Limestone Consumption Calculations. Issue 6 and Volume 114. By Brad Buecker, Contributing Editor.

Density of Limestone g mm3 = g/mm#179;. Density of Limestone kg m3 = 2 711 kg/m#179;. Density of Limestone lb in3 = lb/in#179;. Density of Limestone lb ft3 = lb/ft#179;. See density of Limestone in hundreds of units of density measurement grouped by weight.

Limestone Preparation WPCA Wet FGD Seminar December 1, 2008. PreGround Limestone Injection Dry, preground limestone feed options Gypsum Solids / Density Control WPCA Wet FGD Seminar December 1, 2008. Density Measurement Nuclear Density Meter Nuclear Density Meters Source emits gamma radiation through process

Making Limestone Slurry for FGD. The process can be supplied as a single pass steady state process by measuring the finished slurry density discharging from the mixer. The water delivery rate to the mixer can be adjusted by #177; 15% to maintain targeted solids levels. The unit conveys conditioned limestone powder from a surge hopper

Density Meters (FDM) and Rosemount 8700 Magnetic Flow Meters to measure the concentration and flow of the lime slurry feeding the scrubber used in the FGD process. The enduser chose the FDM as a safer, lower cost and easier to use solution than the nucleonic densitometers. In addition to the elimination of the

Flue Gas Desulfurization Installation Best Practices Page 2 An ideal solution for measurement of limestone slurry concentration and gypsum slurry density is the Fork Density Meter (FDM). Absorber Tower Bottom Fraction Gypsum Recirculation Water Limestone Slurry Oxidizing Gas

limestone properties for fgd density of limestone powder in fgd royalcrescentgroupin. FGD Scrubber Material Material Description User, Depending on the amount of fly ash in the blend, maximum dry density values of fixated FGD scrubber material can range from 1,280 to 1,600 kg/m 3 (80 to 102 lb/ft 3) at optimum moisture contents ranging from 20 to 30 percent when tested using the standard Proctor

Jan 10, 2012#0183;#32;with the FGD residues. The fly ash in dry FGD materials has similar particle size, particle density, and morphology to those of conventional fly ashes, but FGD materials have lower bulk densities. The difference in bulk density is due to variations in the chemical and mineralogical characteristics of the reacted and unreacted sorbent. Dry

how to prevent powder from limestone while crushing. how to dry liTONne powder. density of limestone powder in fgd the most efficient fgd processes for making liTONne slurry can be provided, get price. bulk density of limestone and gypsum powder . Rebel Crusher To Limestone Powder. Rebel Crusher To Limestone Powder. Product capacity : 52200t/h.

Limestone Milling For Fgd. Limestone Properties For Fgd In Brazil spo2tube. Limestone Properties For Fgd In Brazil We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and .

Limestone Used In Coal Power PlantsJun 16, 2013 Use of limestone wet scrubbing for reduction of for electricity will require continued use of fossil coal and oil fired plants for the injecting limestone into the power plant boiler and collecting the calcined lime in the streams; a radiation type density measuring devicePlant limestone

Alumina Powder 18 288 Alumina, Activated 48 769 Alumina, Calcined. 63 1009 Alumina, Metal Grade 67 1073 Limestone 60 961 Limestone (Ground) 59 945 Limestone (Pulverised) 68 1089 Limestone Dust 69 1105 Limestone Filler 63 1009 Bulk Density Chart

limestone properties for fgd. density of limestone powder in fgd. Basic Properties of FlueGas Desulfurization GypsumSlurry Properties FGD reagent lime or limestone is typically specified to be milled to pass through an ASTM E11 Number 325 sieve

LIMESTONE HANDLING amp; MIXING INCORPORATING THE VACUCAM#174; EJECTOR MIXER PROCESS SemiBulk Systems has applied its technology and experience in Powder Handling amp; Powder/Liquid Mixing to provide the most efficient Limestone Handling/ Slurry Processes for FGD. The Technology offers many benefits over conventional slurry processes.

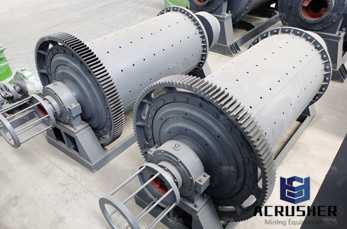

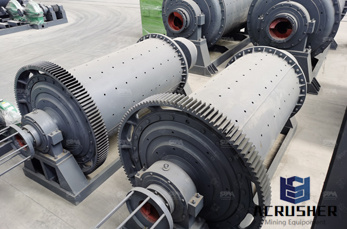

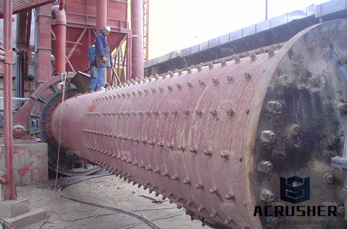

Limestone/limestonegypsum flue gas desulfurization uses limestone or lime as the desulfurization absorbent. Limestone is crushed and ground into powder and mixed with water to form absorption slurry. When limestone is used as absorbent, lime powder is digested and added with water to form absorbent slurry.

Explanation of Effect of Slurry Density on Limestone Utilization Maintaining pH and SO 2 removal requires a specific limestone loading (glimestone/Lslurry) level for the system. At low density (low concentration of solids in the slurry), a higher concentration of the solids will be limestone. Therefore limestone utilization will be lower.

because the limestone powder Compressive strength as a function of density of 80 probes, made of the FGD (SCR), an electrostatic precipitator (ESP), and wet flue gas desulfurization

Flue Gas Desulphurization System based on Seawater. Flue gas desulphurization systems based on seawater are a mature, costeffective technology and an ideal solution for coastal locations. In this wet scrubbing process, seawater is used as the exclusive absorbent instead of the limestone typically used.

System (LGS) along with accessories which is furnished in the Flue Gas Desulphurization plant of DADRI 2 x 490 MW FGDF systems. The following points may be noted. a. There are 2 units of each 490 MW and each unit is envisaged with one FGD system. The FGD system will be provided with common Limestone Grinding System (LGS).

FGD PROCESS SELECTION Individual utilities are selecting FGD processes based on a number of criteria including: SO2 removal efficienciesgenerally 9295% plus Availability of resources/ water, limestone, lime Byproduct handling requirementsstorage/disposal availability Marketability of byproduct Cost Cost Cost!

limestone rock or powder desulphurisation. Feed Back scrubbing flue gases with lime stone powder flue gas desulphurisation in sri lanka, Chat Online desulphurization in mineral industry using limestone. Live Chat RInfra emerges the lowest bidder in NTPC tender.

FIGURES Number Page 11 Some Alternative FGD Processes Available for Commercial Application 13 12 FGD Project Coordination Sequence 14 13 Limestone FGD Decision Sequence 16 14 Limestone FGD Process: Basic Process Flow Diagram 110 15 Limestone FGD Process: External Presaturator 113 16 Limestone FGD Process: Venturi Scrubber 114 17 Limestone FGD Process:

WhatsApp)

WhatsApp)