3 Types of Hammers Every DIYer Should Know Bob Vila

3 Types of Hammers Every DIYer Should Know (and When to Use Them) Get to know the key differences between the claw, ball peen, and club hammer

WhatsApp)

WhatsApp)

3 Types of Hammers Every DIYer Should Know (and When to Use Them) Get to know the key differences between the claw, ball peen, and club hammer

#0183;#32;In this video we will discuss SIZE REDUCTION, by the means of Hammer Mill and Ball mill, it''s construction and working with derivation and formulas for calcu...

The hammer mill will produce discharge in the 2030 mesh size. If additional size reduction is needed, a ball mill is a conventional choice instead of the hammer mill. Take a look at the procedure to determine the liberation size

The least average particle sizes the modified hammer mill produced were, mm, and compared to mm, mm and mm and mm, mm and 0

Grinding Mills and Their Types. satyendra; April 9, 2015; 1 Comment ; autogenous grinding, ball mill, grinding mills, hammer mill, rod mill, roller mill, SAG,; Grinding Mills and Their Types In various fields of the process industry, reduction of size of different materials is a basic unit operation.

If you are looking for the perfect framing hammer size I would recommend the twenty or the twentytwo ouncer. If youre looking for a basic hammer or something a little on the lighter side then I would recommend a twelve or sixteen ouncer. If youre looking for a finishing hammer then anything less then twelve ounces

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

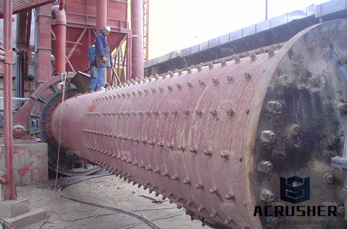

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

hammers are also common in hammer mill designs. Hammer mills are recognized as technology capable of finely grinding the greatest variety of materials [3,13] and are noted for achieving high sizereduction ratios and yielding cubicshaped particles [14,15]. Hammer mills have a wide application in biomass size reduction

A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft. This type of mill uses the same principle as a VSI crusher.. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a

Max Feeding Size (mm) lt;70 lt;90 lt;100: Finished Size(mm) 03: 03: 03: Capacity (T/H) 3550: 5070: 70100: Power (KW) 5575: 7590: 110132: Hammer Number: 18: 16: 32: L*W*H/mm Layout Size:

#0183;#32;Strike the same glass with a sledge hammer, and it will shatter into 1000+ pieces. Summary. Finished particle size is determined by a combination of screen size, rotor speed, and the size and number of hammers. Material must remain in the grinding chamber until it is able to pass through the screen covering the hammer mills discharge opening.

WhatsApp)

WhatsApp)