coal mill sop working principle

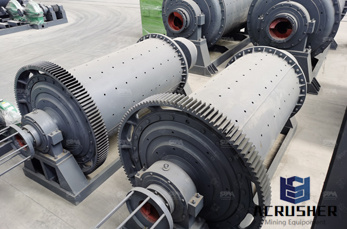

Coal Mill in Power Plant,Working Principle of Ball Mill General use of coal powder particles diameter range of 01000 um, mostly 2050 um particles, so the coal powder to

WhatsApp)

WhatsApp)

Coal Mill in Power Plant,Working Principle of Ball Mill General use of coal powder particles diameter range of 01000 um, mostly 2050 um particles, so the coal powder to

This article aims to describe the working principle of a jet mill. A jet mill, also called fluid energy mill, is used for solid material micronization. Micronization is a term used to describe size reduction where the resulting particlesize distribution is less than 10 microns.

Working principle of coal vertical grinding mill. Working principle of coal vertical grinding mill News Date 14 10 15. Chaeng coal grinding mill system specifications are divided into coal vertical mill, coal vertical mill, coal vertical mill, its capacity design is divided into 20t / h, 25t / h, 40t / h, in order to meet the market demand for a variety

working principle of coal mill. coal vertical grinding mill working principle Great Wall Chaeng coal grinding system specifiions are divided into GRMC17 21 coal vertical mill GRMC19 21 coal mill GRMC24 31 coal mill its capacity design is divided into 20t h 25t h 40t h in order to meet the market demand for a variety of coalfired boiler appliions and the pulverized coal mill is the most leading

raymond mill structure and working principle. The whole structure of Raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other host is composed of a frame, Raymond mill inlet volute, blade, grinding, grinding ring, a cover casing and a motor.

#0183;#32;Principle of operation bowl mill 1. Principle of Operation Bowl Mill is driven by AC motor, coupled with flexible coupling to the worm shaft. The worm shaft drives worm gear, mounted on the Main Vertical Shaft. A bowl mounted on the top of the shaft rotates at a speed of 40 to 65 rpm.

#0183;#32;Working Principle of Coal Grinding Mill. Coal vertical roller mill is a machine that crushes and grinds coal into pulverized coal. It is an important auxiliary equipment of pulverized coal furnace. The vertical mill is a horizontal cylindrical rotating device driven by external gears.

What is the working principle of coal mill? News Date: 16:41:48. Chaeng coal grinding system specifications are divided into: coal vertical mill, coal mill, coal mill, its capacity design is divided into: 20t / h, 25t / h, 40t / h, in order to meet the market demand for a variety of coalfired boiler applications, and the pulverized coal mill is the

coal mill sop working principle Mine Equipments. Coal Mill in Power Plant,Working Principle of Ball Mill General use of coal powder particles diameter range of 01000 um, mostly 2050 um particles, so the coal powder to make coal mill

coal mill sop working principle. Coal Mill in Power Plant,Working Principle of Ball Mill. General use of coal powder particles diameter range of 01000 um, mostly 2050 um particles,

Working of the Colloidal Mill. The material is placed into the mill though the inlet hopper. It is then passed through the narrow gap between the rotor and stator and thus reduced the fine particle size. A colloid mill is a hydraulic shear producing device. The colloid mill works to reduce the size of the suspended droplets.

SCM provide the coal mill sop working principle solution case for you coal mill sop working Fine pulverizer in stone crushing Chat Now What is the working principle of ball mill Quora Oct 22 2013 Ball Mill Working principle When the ball mill works motor and speed reducer transmit torque force to big and small gears of ball

SCM provide the coal mill sop working principle solution case for you coal mill sop working Fine pulverizer in stone crushing Chat Now What is the working principle of ball mill Quora Oct 22 2013 Ball Mill Working principle When the ball mill works motor and speed reducer transmit torque force to big and small gears of ball

working principle of coal mill Crusher South Africa. Oct 13, 2012 #183;amp;nbsp working principle of raw mill. Working principle of ATOX raw mill | Crusher and Vertical roller mills are widely accepted as the most efficient

coal mill sop working principle SBM Ball Mill. SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the coal mill sop working principle, sand amp; gravel, quarry, mining, construction and

Working principle. Three stationary grinding rollers roll on a rotating grinding table. MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine. MPS 3070 BK coal mill, Jaypee Cement Balaji, India. MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia.

#0183;#32;Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mills main components, how it works and some of its design...

Coal mill sop working principle coal mill sop working principle. ufr lced#233;partement d''#233;tudes anglophonesthe mines act, 1842, coal was the major source of british mining incomes through the nineteenth century, women and children had the key role of wage earner when belonging to poor families of the working class, in a pit near new mills'', says the subcommissionner, ''the

To lay down the procedure for operation of Cad mill. SCOPE This SOP shall be applicable for the Cad Mill in Granulation Area at Production department. RESPONSIBILITY Execution: Operator Checking: Production Pharmacist amp; Above ACCOUNTABILITY HODProduction / Assigned Designee PROCEDURE

WhatsApp)

WhatsApp)