processing of coke coal

Coal tar is a byproduct generated while processing coking coal into low ash metallurgical coke in a recoverytype coke oven plant. Read more CNA Google

WhatsApp)

WhatsApp)

Coal tar is a byproduct generated while processing coking coal into low ash metallurgical coke in a recoverytype coke oven plant. Read more CNA Google

Metallurgical coke is produced by the destructive distillation of coal in coke ovens. Prepared coal is heated in an oxygenfree atmosphere (coked) until most volatile components in the coal are removed. The material remaining is a carbon mass called coke. Metallurgical coke is used in iron and steel industry processes (primarily in blast furnaces) to reduce iron ore to iron.

Coke is produced by igniting bituminous coal under reduced oxygen conditions in oven batteries specially designed for this process. The coking process generates the following main volatiles as byproducts: coke oven gas, tar, ammonium sulfate, benzol, toluol and naphtha.

Aug 21, 2020#0183;#32;Coke making is effectively the carbonization of coal at high temperatures. Production normally takes place in a coke battery located near an integrated steel mill. In the battery, coke ovens are stacked in rows. Coal is loaded into the ovens and heated in the absence of oxygen up to temperatures around 1,100 degrees Celsius (2,000 degrees

Coke Production General Metallurgical coke is produced by the destructive distillation of coal in coke ovens. Prepared coal is heated in an oxygenfree atmosphere (coked) until most volatile components in the coal are removed. The material remaining is a carbon mass called coke.

#0183;#32;from the carbonization (heating) of coal, which produces coke, combustible gas, and a number of byproducts, including benzene. Carbonization of coal to produce illuminating gas dates back in England to the very early years of the 19th century. The process is still employed in some countries, but more use is Read More; coke production

Coal needs to be stored at various stages of the preparation process, and conveyed around the CPP facilities. Coal handling is part of the larger field of bulk material handling, and is a complex and vital part of the CPP.. Stockpiles provide surge capacity to various parts of the CPP. ROM coal is delivered with large variations in production rate of tonnes per hour (tph).

Jun 22, 2016#0183;#32;Quality of coal In either coke or noncoked coal, the quality of the coal affects the quality of the steel. Metallurgical coke is made from bituminous coals by a distillation process. Ash deposited by the coal must be kept to a minimum, preferably below 10% of the original mass.

Coal carbonization is used for processing of coal to produce coke using metallurgical grade coal.... Various products from coal carbonization in addition to coke.

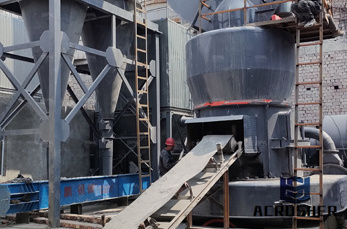

Coke Handling and Processing Equipment Header, Belt Conveyor Rotary Dryer (Drier) for Coke Drying in the Steel Industry Image: The image above shows a belt conveyor that would be typical at a coal, coke, or pet coke handling facility; the conveyor is equipped with weather covers, an integrated skirtboard, and exhaust ports to manage dust near the inlet chutes.

Coke Production US EPA

Coal processing. Fluid coke description fluid coke is the carbonization product of highboiling hydrocarbon fractions heavy residues of petroleum or coal processing produced by the fluid coking process see carbonization notes fluid coke consists of spherulitic grains w... Details

Metallurgical Coke Oxbow. Processing. Metallurgical coal is used in the production and purification of metallurgical coke. It is during the heating process that the unstable components are released. The final product is a nonmelting, solid, stable carbon.

Coke Handling and Processing Equipment Header, Belt Conveyor Rotary Dryer (Drier) for Coke Drying in the Steel Industry Image: The image above shows a belt conveyor that would be typical at a coal, coke, or pet coke handling facility; the conveyor is equipped with weather covers, an integrated skirtboard, and exhaust ports to manage dust near

coal today comes from the energy that plants absorbed from the sun millions of years ago. Coal is used primarily as an energy source, either for heat or electricity. It was once heavily used to heat homes and power locomotives and factories. Bituminous coal is also used to produce coke for making steel and other industrial process heating.

Petroleum coke, abbreviated coke or petcoke, is a final carbonrich solid material that derives from oil refining, and is one type of the group of fuels referred to as cokes. Petcoke is the coke that, in particular, derives from a final cracking processa thermobased chemical engineering process that splits long chain hydrocarbons of petroleum into shorter chainsthat takes place in units termed coker units.

Coal gasification WikipediaCoal gasification is the process of producing syngasa mixture consisting primarily of carbon monoxide (CO), hydrogen (H 2), carbon dioxide (CO 2), natural gas (CH 4), and water vapour (H 2 O)from coal and water, air and/or oxygen Historically, coal was .What Is Metallurgical Coke? | SciencingMetallurgical coke sounds like a soda beverage, but it''s not It is a

This process results in a hard porous material coke. Coke is produced in a coke battery, which is composed of many coke ovens stacked in rows into which coal is loaded. The coking process takes place over long periods of time between 1236 hours in the coke ovens.

The process in which conversion of coal to coke takes place is referred to as coal carbonization. Coke is nothing but a carbonaceous material solid in nature which is again derived through the process of destructive distillation of low ash, lowsulfur and bituminous coal. The transformation of coal to coke is better known as the cokemaking

Oct 04, 2018#0183;#32;Coal is the main ingredient used to make coke. Iron is produced by inputting coal into a blast furnace. However, coal cannot be put directly into a blast furnace because of all the harmful byproducts that come from that. So, there is an intermediate process that occurs. Coal is converted into coke first. Coke is used as fuel in a blast furnace.

Coaltar pitch is particularly valuable to anode and electrode manufacturers The mam function is to plasticize coke grist so that formed bodies can be extruded or molded without distortion during the later stages of processing Additionally, the pitch should give a highcarbon yield and not adversely affect the overall properties of the finished

Coal is a mineral consisting mainly of sedimentary fossilized carbon with smaller amounts of other elements, such as sulfur, hydrogen, oxygen, nitrogen and m...

(c) The black thick liquid with an unpleasant smell is known as coal tar. (d) During the processing of coal to get a coke, coal tar and coal gas are also obtained. (e) The process of separating the various constituents of petroleum is known as refining. (f) Excessive burning of

WhatsApp)

WhatsApp)