Storyboards / Storyboard Artists in Colorado

Dec 14, 2020#0183;#32;Production guide and directory with crew, equipment, digital media, preproduction, post production, production support and talent services. Search, get listed, or request production

WhatsApp)

WhatsApp)

Dec 14, 2020#0183;#32;Production guide and directory with crew, equipment, digital media, preproduction, post production, production support and talent services. Search, get listed, or request production

Basalt rock characteristics vary from the source of lava, cooling rate, and historical exposure to the elements. High quality fibers are made from basalt deposits with uniform chemical makeup. The production of basalt and glass fibers are similar. Crushed basalt rock is the only raw material required for manufacturing the fiber.

Basalt fiber technologies Basalt Fibers Pressreleases A new Mafic plant became the first of its kind in USA and the largest producer of basalt fibers in the world quot;The production of basalt fiber on a largescale will be a gamechanger in a number of industriesquot;, Mike Levine, CEO Mafic.

Construction works. Ordering and equipment manufacturing. Utility connections. Staff recruiting and training 1. The estimated range of CBF produced: Roving linear density of from 60 0 to 4800 tex, filament diameter of 920 For the production of basalt rovings (various tex) apply doubling machines brand DS35EE with the creel.

Aug 02, 2019#0183;#32;Indian customer Smile Keakile selected China VSI sand making machine for his sand production line, and he adopted both efficient and environmentally friendly artificial sand making way for treating basalt. The VSI sand making production line has the reasonable layout, small area, costeffective investment, environmental protection, less dust pollution, energysaving, and high efficiency,

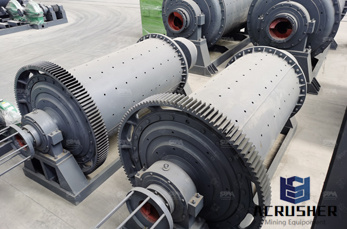

The equipment has already proven its worth: in a new open quarry in Germany, hard and very heavy basalt with a density of t/m#179; is extracted and processed into aggregates suitable for asphalt and concrete as well as for ballast and amour stones. There, all products meet the highest quality standards.

Figure 1. Basalt fiber. Equipment and technology The raw materials and energy are basalt, gas, electricity, and impregnating compound. The equipment is gas or electricity wire drawing kiln, Platinum rhodium alloy bushing, crusher, applicator, impregnating compound configuration and conveying equipment, roving machine and loom.

Basalt deposits the result of volcanic lava exits is present in almost every country. The major basalt fields, whose suitability for CBF production has been confirmed in the lab, are located in Ukraine, Russia, Uzbekistan, Georgia, Saudi Arabia, Ethiopia, China, India, Brazil and other countries.

Installation of STBF production equipment is done stebbystep: installation and launch of the first union, then the next, with an interval of 2~3 months. Client should prepare industrial premises and communications, including gas, electric power, compressed air, water, ventilation amp; smoke removal system (air lines, chimney).

Basalt Center has experience and essential technical and technological expertise necessary for designing and manufacturing of highquality equipment from various feedstocks in order to produce a variety of products according to the customers requirements.. The equipment for manufacturing composite components is a crucial point for producing high quality products.

Mar 10, 2011#0183;#32;The first continuous basalt fibres of satisfactory quality were produced with laboratory equipment in 1963. A great deal of work followed to develop CBF production technologies and equipment, to study fibre characteristics, to develop CBF material

Technobell is a longstanding engineering company specialising in process and project design as well as equipment construction, especially in the fields Technobell Technology. United Kingdom Composite materials and Composite manufacturing with pultrusionm RTM, SMC/BMC, winding, injection.

AO quot;KPGabbroquot; is the second quarry in Russian Federation bought by quot;Basalt AGquot; company. Active construction of the quarry in Navolokskoe occurrence is being carried on now: there are demolition works, access railway is being built, equipment is received and assembled.

We offer to buy equipment for the highyielding production of fibreglass or basalt fibre reinforcing mesh. Our equipment is the most reliable, highly productive and unique! Our fibreglass reinforcing mesh production equipment is a nextgeneration equipment giving you

Basalt multiend roving consists of mutifilaments produced at the continuous basalt fibre production facility and then assembled together in a doubling winder. The main applications of basalt roving and basalt composites include mechanical engineering, aerospace, shipbuilding, automotive, chemical and oil industry, energy production, electronics, manufacture of composite building materials, public utilities.

The basalt raw material is reduced to fractures 5 ~ 20 mm in dimension the basalt fractions are fed by the charging conveyer (1) to the melting furnace (2) the charged basalt is melting at a temperature of 1400 ~1600 #176;C the melted basalt passes through the die holes of the bushing (3) from the bushing, the basalt continuous fibers 9 ~ 15 mm in diameter (4) are fed to the unit (5) for applying lubricant

These studies exclude the possibility of obtaining lowquality continuous basalt fiber and breakage of expensive equipment, which leads to financial damage to the enterprise. The final stage in the study of rocks is pilotindustrial melting at the operating enterprise and the production of the resulting fiber of the finished product, such as rebar.

Manufacture, supply, installation, and commissioning of the first priority equipment of the TE BCF production line rated at the productivity of ton of basalt continuous fiber per year, and complex equipment for production of the finish BCF products, including: driers for primary continuous basal fiber and basalt fiber roving, rewinding units for BCF roving, and units for cutting basalt fiber

Serious research of production area of continuous basalt fiber started simultaneously in the USA and in the USSR in the 60s. as a result, S2glass was created. In the USSR works with basalt fiber continued up to the end of the 90s, they took place mainly in Ukraine. as thermal insulation for industrial equipment, furnaces

Technological equipment of the production of CBF and the main components are protected by patents for inventions that have global priority (the author and owner of patents, Osnos ): 77861 UA Method and device for the production of fibers from basalt rocks. 90065 UA Method of production of basalt continuous fibers from and

The concept of composite production. When planning Basalt FiberReinforced Polymer (BFRP) Composite production, a line of technological equipment is selected for the production of products in demand on the market, which allows to reach the selfsufficiency of the enterprise in

Basalt Rebar production line for composite material Basalt fiber composite re bar is made of high strength basalt fiber and resin through online pultrusion, winding, surface coating and composite molding, continuous production of new building materials.

Basalt feeding equipment price [ 9778 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the

WhatsApp)

WhatsApp)