Ball Mill Design/Power Calculation LinkedIn

#0183;#32;The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific

WhatsApp)

WhatsApp)

#0183;#32;The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific

Optimization of mill performance by using online ball and pulp measurements J o u r n a l P a p e r The Journal of The Southern African Institute of Mining and Metallurgy VOLUME 110 NONREFEREED PAPER MARCH 2010 135 Table I Influence of speed and liner design on load dynamics Mill speed Soft design Aggressive design

Coal Ball Mill Design Calculations. bearing load calculation a22 2loads acting on cross shafts gear loads acting on straight tooth bevel gears and spiral bevel gears on cross shafts are shown in figsand4the calculation methods for these gear loads are....

BallRace Mills comprise the majority of coal pulverizers currently in service at power generating facilities. Figure 3 shows a cutaway of a RingRoll type coal pulverizer. In this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Get coal ball mill design calculations Price. You can get the price of coal ball mill design calculations and a AampC representative will contact you within one business day. Page 1 Ball Milling Theory. With most ball mill designs, you have two areas of speed reduction to tweak from the motor drive shaft to the drive pulley and from the roller

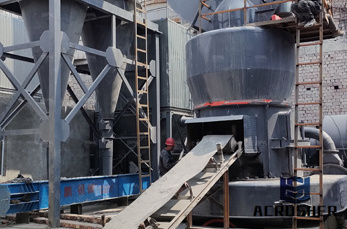

Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%40% similarly. Applications: Cement, coal, power plant desulfurization, metallurgy, chemical industry, nonmetallic mineral, construction material, ceramics. Grinding Mill China coal silo design calculation xls, coal silo design examples

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or

coal hammer mill sizing calculation. There are forty years of manufacturing history, with three major production bases,over 160 senior Ramp;D engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ leading products have crushing equipment, sand making equipment, mobile

Design Method of Ball Mill by Discrete Element Method collected. The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation). Details of the experimental conditions are given in Table 2. Results and Discussion 1. Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis

Types of coal pulverizers. Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills. A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length of meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter. The lengthtodiameter ratios in the previous table are for normal applications.

Ball Mill Design/Power Calculation

Ball Mill Design Calculation In India. critical speed of ball mill calculation india. speed of ball mill calculation india the critical speed can be understood as that speed after which the ste aside from common ball mills there is a second type of ball mill called plaary ball mill the point where the mill becomes a centrifuge is called the critical speed and ball mills usually operate at 65

Ball Mill Design/Power Calculation. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and

Taking design influences from coal mine buildings that established the towns of Cle Elum and Ronald, Washington, this retreat takes in views of Lake Cle Elum to the West and Red Mountain to the North. Besides the mine influence and taking in the views, the environment was a major driver in the design.

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal

Coal ball mill design calculations coal mill charge ball calculation our company is a leading highend j boring machine equipment supplier mainly engaged in mine mining machinery equipment get price and support online coal ball mill design calculations prices of grinding coal ball mill design calculations.

Hammer Crusher Size Proportion. Hammer Mill Crushergrinding mill/ultrafine mill/ball Hammer Mill Crusher engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPa into fine and micro fine powders, is widely used in metallurgy, mining, chemical, cement, coal, sandmaking, coal gangue, construction, refractory materials and ceramic industries.

coal ball mill design calculations Grinding Mill China. ball mill design calculations Coal Surface Mining. ball mill design calculations Description : ball mill design calculation in

WhatsApp)

WhatsApp)