Ball Mill Design/Power Calculation LinkedIn

#0183;#32;Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size

WhatsApp)

WhatsApp)

#0183;#32;Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size

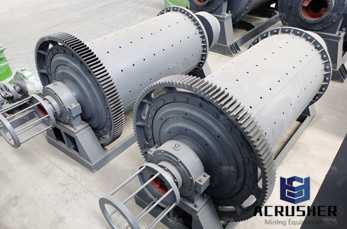

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill

Capacity (25% of total) Total Volume WET Working Capacity (60% of total) rpm DRY milling 60% of critical Gear amp; Pinnion Drive used on Larger Mills JH 32014 Talk with the Experts sales _____ Since 1911 phone fax B Ball Mill Capacity amp; Dimensions

Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length of meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter. The lengthtodiameter ratios in the previous table are for normal applications. For primary grinding, the ratio could vary between 1:1and

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to

Ball Mill Design Calculation Price India cement ball mill types. (design, operating measurements and calculations for determination of gas and airflows optimization of usa ball mill manufacturer in india HP and above {5 Kg to 10 tons Capacity / Continue Ball Mill}

The bigger ball in relation to the optimal one will have an excess energy, and consequently, the smaller ball mill has less energy necessary for grinding. In both cases, the specific power consumption increases and the grinding capacity decreases (Concha et al. 1992;

laboratory ball mill. This method is based on two power calculation approaches used in ball and rod mill design processes due to its simplicity and workability. The first approach, which is specific power calculation, determines the power required to grind an ore from a given feed size to a specific product size. The second

Ball Mill Design/Power Calculation Mineral Processing amp; Metallurgy. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill

Key Words: SAG mill, design, optimum conditions, grinding, pilot testing 1. ABSTRACT A great deal of effort has been expended in the last 11 years by the authors and others to identify the correct power required to grind ore in a SAG mill, by developing ore hardness variability functions for the ore body to

Ore Ball Mill Machine Design Capacity Calculation. new and used ball mills for sale savona equipment is a new and used ball mill supplier worldwideball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

complete design of ball mill for college project. ball mill design in mining project. The basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are material to be ground characteristics Bond Work Index bulk density specific density desired mill tonnage capacity DTPH operating solids or pulp density feed size as F80 and maximum ''chunk size'' product

Calculate Ball Mill Grinding Capacity The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of appl

WhatsApp)

WhatsApp)