Hammer mill design calculation YouTube

#0183;#32;Now chatting: Contact Us: basic design calculations of hammer mill MTM Crusher Down...

WhatsApp)

WhatsApp)

#0183;#32;Now chatting: Contact Us: basic design calculations of hammer mill MTM Crusher Down...

SIZE HAMMER MILL AJAKA and ADESINA A. the hammers while in operation was also considered in the design. Swinging instead of stiff hammers was used to avoid the rotor or the hammers from getting stocked in case a hammer Twisting of the shaft is neglible from the torsion rigidly calculation

Basic design calculations of hammer mill pochirajucoin a scaleup model of the hammer mill is established based on the energysize relation to predict the mill capacity as a function of the mill design and the operating parameters the reliability of the back calculations was also improved by live chat calculation of power for a hammer mill pdf .If you want to learn about our products, please

The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources . The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile. Further more, the hammer was redesign to twisted type as

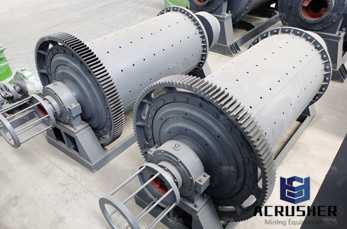

Ball Mill Design/Power Calculation. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally

Hammer Mill Design Calculation Pdf. Posted on by . SAVE IMAGE. Pdf Redesign And Manufacture An Impact Crusher Hammer Mill Using. SAVE IMAGE. Design Fabrication And Testing Of A Laboratory Size Hammer Mill1. SAVE IMAGE. The Working Principle Of Hammer Mills

Schematic of design hammer mill 1Main frame,2Single phase Electrical motor 1 k Watt, Twisting of the rotational shaft is neglected from the torsion rigidly calculation.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

hammer mill power design calculation. The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials basic parameters used in ball mill design (power calculations)rod mill or any tumbling mill sizing are; material to be groundcharacteristicsBond Work Indexbulk densityspecific densitydesired mill tonnage

T 481 Egypt. J. Agric. Res.,93 (5) (B). 2015

pdf hammer mill design calculation,PDF On Dec 18 2015 Hanafi A Radwan and others published DESIGN AND EVALUATE OF A SMALL HAMMER MILL Find read and cite all the research you need on ResearchGate Design calculation

#0183;#32;A homemade hammer mill is shown in this video. It can be used for crushing stones and all other nonmetallic materials. For hammer mill operation view the vi...

Hammer mill power design calculation charge for the grinding mill pdf calculation of power for a hammer mill pdf cachedcapacityammer mill sizing calculation pdfgrinding mill china hammer mill design timation of motor power estimation of motor power output for crushing by screen hammer mills we can calculate the momentary electric power p.

Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, prime mover in the screen, hammer design and placement that will provide maximum contact with the feed ingredient [5].

mills have intrinsic cooling due to compressed air expansion in the body of the mill. With the help of sweeping air, hammer mills may also be able to process materials with low melting points for coarse grinding applications. Explosibility. The risk of dust explosions must be taken into account when a material is ground very fine in a milling

2 Sammons Court Bolingbrook, IL 60440 Tel: Fax: Toll Free: Email: info Web site: Partial List of Materials Processed by Prater Hammer Mills P00504/06 Alfalfa Aluminum Foil

Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact. The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer

The design of the special hammer mill for drying will have a rotor diameter of m and a rotor width of m and a power requirement of 269 kW. Since this is lower than the power requirement stated to be necessary above, of 309 kW, a larger special hammer mill with a rotor diameter of m and a rotor width of m and a power requirement of 313 kW will be selected.

WhatsApp)

WhatsApp)