Why is limestone used for making paper white? Answers

The pulp industry uses lime in various stages of the production process: Why is limestone used for making paper white? Asked by Wiki User. 7 8 9. makes the paper turn white. it also makes

WhatsApp)

WhatsApp)

The pulp industry uses lime in various stages of the production process: Why is limestone used for making paper white? Asked by Wiki User. 7 8 9. makes the paper turn white. it also makes

The clear white water stream may be discharged to wastewater treatment, or it may be further filtered to make it suitable for use in showers on the paper machine. The air content of white water is kept to a moderate level by the design of a quot;trayquot; and quot;silo.quot; These structures allows bubble of air time to rise to the water

Step 1: Our pulp and paper process. Paper for recycling is mixed with processed water and then stirred in a giant stainless steel vat, called a pulper, to make a fibre suspension. Impurities are removed using a series of screens, to ensure that we only produce highquality paper that can be used to make highperformance packaging.

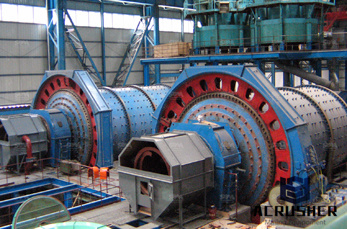

The white water recovery can reduce the fiber loss, Leizhan supply high quality paper machine and design the project for paper making friends to maximize the benefits and the lowest fiber loss, if you have any need or questions, welcome to consult us.

Limestone quarries and stonemasons are always wondering how to reduce the amount of waste they have to dispose of. One solution might be to turn it into paper. A company is making paper in just that way, using 80% powdered CaCO 3 (limestone) and 20% resin. The

Sep 06, 2013#0183;#32;Making paper yourself is a bit timeconsuming but not especially complicated, and you probably have most or all of the necessary raw materials.

process of making paper white with limestone. Uses for Limestone Powder Sciencing. Limestone can be used in pigmentmaking and as a filler for more expensive paints. Paper is also manufactured using limestone. Wood is treated with acid to help break it down which is then treated with limestone to neutralize the acid and whiten paper.

Essential to the process are the fibers, which are never totally destroyed, and, when mixed and softened, form an interlaced pattern within the paper itself. Modern papermaking methods, although significantly more complicated than the older ways, are developmental improvements rather than entirely new methods of making paper.

The paper and cardboard industries use limebased coating pigments and fillers such as GCC where the local marble is extremely white. The producer of GCC in Lappeenranta is Nordkalk''s subsidiary Suomen Karbonaatti Oy. Precipitated Calcium Carbonate Nordkalk is the leading limestone company in Northern Europe.

Chapter 2The Pulp and Paper Making Processes 19 Figure 21Overall View of Papermaking From Chemical Pulp by the Kraft Process Continuous digester II White liquor clarifier Wash water I I Stripped condensates A SOURCE: Envirorwnent Ontario,Sropng Water Poflutioft Al Its Source (Toronto,OntarIO: Ministry of the Environment, 1988).

You can turn limestone white again by using muriatic acid. Caution must be applied when using this acid and you must wear protective gloves and eye goggles. You will have to wash the acid away

Jan 01, 2013#0183;#32;Calcium carbonate is used in paper mill as a filler material in the alkaline papermaking process. Now a days Calcium carbonate dominant over other papermaking filler materials; though at the first stage of papermaking kaolin was 1st choice. The main reason behind the preference of calcium carbonate is the demand for brighter and bulkier paper.. There are significant benefits to the use of

Stone paper, also known as limestone paper, rock paper, generically referred to as bioplastic paper, mineral paper or rich mineral paper, is a type of strong and durable paperlike material manufactured from calcium carbonate bonded with small amount of resin highdensity polyethylene (HDPE). It is used for stationery, leaflets, posters, books, magazines, bags, packaging, wallpaper, adhesives

Home gt; Process of limestone paper. Process of limestone paper. wood chips are digested at elevated temperature and pressure in white liquor, A Startup Making Paper Out of Stone, Not Trees Hac . Jun 16, 2017 To process limestone

This inked surface is then printedeither directly on paper, by means of a special press (as in most fineart printmaking), or onto a rubber cylinder (as in commercial ). The process was discovered in 1798 by Alois Senefelder of Munich, who used a porous Bavarian limestone for his plate (hence lithography, from Greek lithos, stone).

Oct 23, 2018#0183;#32;Use plain white if you want white paper; printed/recycled office paper will yield a light grey, and/or you can mix in some colored paper. Experiment with various paper types (text weight, cotton, card stock) to vary the resulting colors and textures. Put the lid on the blender and turn it on.

This is what you will need to make paper:5 sheets of construction paper.(you can use any type of paper you have at home that does NOT have a shiny coat or wax on it)2 sheets of white paper (optional)About 3 gallons of warm water.(you won''t necessarily use the entire amount)A big enough container to hold that much water and fit the mold. A mold to make the paper (you can see my other

The limestone cycle Calcium carbonate. Calcium carbonate, calcium oxide and calcium hydroxide are all made from limestone and have important applications so it is important to know how they are made.

A simple manufacturing process. Limex is made by mixing finely powdered limestone and polyolefin resin while adding heat. The company received a Japanese patent for its production method in January 2014, and its international patent applications have been approved or await approval in 43 countries.

Limestone is an essential mineral commodity of national importance. Some of the many products made using limestone are shown in this photographbreakfast cereal, paint, calcium supplement pills, a marble tabletop, antacid tablets, highquality paper, white roofing granules, and Portland cement.

Sappi is a global company focused on providing chemical cellulose, paperpulp and paper based solutions to its direct and indirect customer base across more

Products made with limestone: Limestone is an essential mineral commodity of national importance. Some of the many products made using limestone are shown in this photograph: breakfast cereal, paint, calcium supplement pills, a marble tabletop, antacid tablets, highquality paper, white roofing granules, and Portland cement.

#0183;#32;The process of making paper from stone is not entirely new. The process was first developed by the Taiwan company Lung Meng Tech Co. in 1998. Their version, called Stone Paper, is made from leftover marble, crushed to a powder, and plastic.

WhatsApp)

WhatsApp)