Ball Mill Design/Power Calculation LinkedIn

#0183;#32;Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350

WhatsApp)

WhatsApp)

#0183;#32;Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350

Energy Volts Needed To Power Two Grinding Mill; Energy Volts Needed To Power Two Electric Motor for VKP1024 Deluxe Grain Mill 120 Volts AC 60 Hz 075 Amp 90 Watts 50 RPM VKP1024M ENERGY EFFICIENT Low power consumption minimizes energy expense and allows for use with emergency power source 120 VAC 60 Hz slow Also the mill itself you just cant

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to

energy volts needed to power two grinding mill in malaysia. Dec 12 2016 #183; If P is less than 80 passing 70 microns power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is . Leave Message Get a Quote

First, we have to agree on a type of unit to be used. I prefer using Watts, since it gives quot;how much energy does a city of 1M consume continuously, on averagequot; Also, we need to specify a city in which country, because sometimes the difference is h...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Electric Motor for VKP1024 Deluxe Grain Mill, 120 Volts AC, 60 Hz, Amp, 90 Watts, 50 RPM, VKP1024MENERGY EFFICIENT: Low power consumption minimizes energy expense and allows for use with emergency power source 120 VAC, 60 HzThe first time was to grind one cup of soft white wheat berries and then two and a half cups of hard red

Calculation of energy required for grinding in a ball millCalculation of energy required for grinding in a ball mill. The grindingproduct size, P, in a Bond ba energy volts needed to power two grinding mill

Calculate threephase motor power consumption by multiplying amps by volts by the square root of three (W = AV(sqrt 3). For example, if the motor is drawing 30 amps at 250 volts, you have 30 x 250 x sqrt 3 (about ) = 12,975 watts). Convert watts to kilowatts by dividing the number of watts by 1,000.

The circuit comprises a SAG mill, 12 m diameter by m length (belly inside liners, the effective grinding volume), two pebble crushers, and two ball mills in parallel closed with cyclones. The SAG mill is fitted with a 20 MW gearless drive motor with bidirectional rotational capacity.

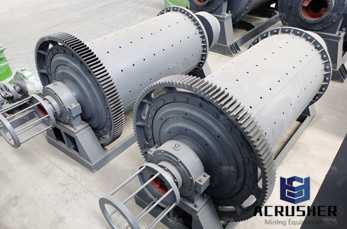

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding The difference between power and energy is that power (kilowatts [kW]) is the rate at which electricity is consumed, while energy (kilowatthours [kWh]) is the quantity consumed. Read Article. Ball Mill Power Calculations

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

Grinding energy was approximately 50 per cent of the ball mill and the drying capabilities allowed direct processing of materials of up to 20 per cent moisture content. The main energy issue was the high power consumption of mill fans, with pressure drops of 100mbar not uncommon with high nozzle ring velocities (gt;70m/s) and internal mill circulating loads of gt;1000 per cent.

the right type of mill, how to operate your mill efficiently, and how to maintain your mill. There are numerous types of grinding mills. This article focuses on two widely used types: the hammer mill and the jet mill. Hammer mills are often used for generalpurpose grinding and

Wind turbines are capable of spinning their blades on hillsides, in the ocean, next to factories and above homes. The idea of letting nature provide free power to your home may seem appealing, but it''s important to learn how to compute wind turbine output before buying one and particularly important to understand the difference between the rated capacity of the machine and the actual output

This mechanical power can be used for specific tasks (such as grinding grain or pumping water) or a generator can convert this mechanical power into electricity. A wind turbine turns wind energy into electricity using the aerodynamic force from the rotor blades, which work like an airplane wing or helicopter rotor blade.

#0183;#32;Bond ball mill grinding test, Bond rod mill grinding test. Bond pendulum test. In this test, the energy required to crush a dry ore particle by the impact of two swinging hammers is determined. The standard method adopted by Bond is as follows .

Good question. Glad to see you asked volts instead of amps. Generally ANY power source will be able to produce substantial current to kill you but most do not supply enough voltage. Static discharges are the exception but then again they aren''t po...

It follows that in order to obtain the speci c energy (SE) to achieve a certain transfer size, based on the 80 per cent passing value, an inef ciency factor must be applied to the SE of single stage ball mills, rod mills or AG/SAG mills when calculating power according to the Bond Third Theory method.

This page is about calculation of power consumption for ball mills and grinding, reduce circulating load of ball mill Ball mill energy saving method two: Iron ore crushing is actually the preparation process that are needed for decreasing the size of iron ores during all iron ore processing technology

WhatsApp)

WhatsApp)