Cement manufacturing process SlideShare

Jun 10, 2014#0183;#32;Portland Cement (contd) Basic Chemical Components of Portland Cement: Calcium (Ca) Silicon (Si) Aluminum (Al) Iron (Fe) Typical Raw Materials: Limestone (CaCO3) Sand

WhatsApp)

WhatsApp)

Jun 10, 2014#0183;#32;Portland Cement (contd) Basic Chemical Components of Portland Cement: Calcium (Ca) Silicon (Si) Aluminum (Al) Iron (Fe) Typical Raw Materials: Limestone (CaCO3) Sand

Aug 30, 2012#0183;#32;Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and

Cement manufacture, like many other manufacturing processes, begins at the mine, where the raw materials like limestone, silica, aluminates, feric minerals and others are obtained. Some typical materials used for calcium carbonate in cement manufacturing are limestone, chalks, marbles, marls, and oyster shell.

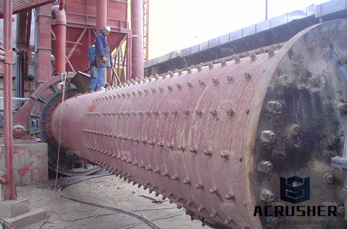

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes, rivers and waterways. There are a few

Aug 30, 2012#0183;#32;Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand amp; clay fulfill the need of silicon, iron and aluminum.

Dec 11, 2020#0183;#32;India: Larsen amp; Toubro has secured 90 contracts for the supply of mining equipment to industrial companies, including various cement producers. The company says that the

Dec 07, 2018#0183;#32;Dozens of variables come into play in the cement production process, from the quality of the limestone and the coals chemical properties to the type of fuel in the kiln and the desired quality

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 #176;C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are recombined into new compounds.

Cement The major cements: composition and properties; Cement manufacturing components of a cement plant. Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement

Mining Component Of Cement Process. Drilling and mining process in cement industry Manufacturing process all about cement cement lafarge the cement manufacturing process starts from the mining

Finish Milling Process Of Cement. Finish Milling Process Of Cement Milling Equipment finish milling process of cement A class of machinery and equipment that can be used to meet the production

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4)

in the figure, the process can be divided into the following primary components: raw materials acquisition and handling, kiln feed preparation, pyroprocessing, and finished cement grinding. Each of these process components is described briefly below. The primary focus of this discussion is on

Proven and adaptable process control. With more than 1500 active product and process control installations in the cement industry and a steadily growing number in the mining industry, the ECS/ControlCenter platform is a trusted process control solution for cement and mining businesses around the world. Its a key component of our growing portfolio of digital solutions and services that we

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes, rivers and waterways. There are a few underground limestone mines, but most are pits on the surface.

Mining Component Of Cement Process. Drilling and mining process in cement industry Manufacturing process all about cement cement lafarge the cement manufacturing process starts from the mining of raw materials that are the limestone is excavated from open cast mines after drilling and blasting and slag a steel industry +

Cement Manufacturing Process | Phases | Flow Chart | Cement

Proven and adaptable process control. With more than 1500 active product and process control installations in the cement industry and a steadily growing number in the mining industry, the

The mining sector enters significantly in the cement industry, this sector is considered the most important in terms of extraction, mining, and processing of raw materials.

The Process Grinding Of The Cement. The Cement Manufacturing Process Advancing Mining. Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 176C in a cement

The whole process of cement manufacturing in Messebo Cement plant which consists of The quarry (where the mining activity is performed) is located km away from the plant and has the main raw

WhatsApp)

WhatsApp)