Boiler Performance and Mill Outlet Temperature Bright

Boiler Performance and Mill Outlet Temperature Bright

WhatsApp)

WhatsApp)

Boiler Performance and Mill Outlet Temperature Bright

Mill Inerting Systems Presentation to the ASBCUG. Typical temperature inside the mill with Coal Moisture of 3% Less Moisture = Lower Mill Inlet Temperatures despite the Higher Outlet Temperature. 100,000 LBS/HR Coal X 3% Moisture = 3,000 Moisture.

Boiler Performance and Mill Outlet Temperature Bright. Two major parameters which decide the mill capacity and performance are the hardness of coal and the total moisture level in coal. The mill outlet temperature of coalair mixture is maintained between 65 to 90 degree centigrade in the case of low and medium volatile coal.

coal drying equipment and impact of fuel moisture on plant performance and temperature (the temperature of the coal and primary air mixture at mill exit), be transferred to the working fluid (water or steam) in the boiler convective pass. Keep the maximum mill outlet temperature to reduce air bypassing... Get price. Performance

Reference: Impact of Minimum Load Operation on Steam Turbines, EPRI 2013 Technical Report () coal distribution, mill outlet temperature, and fineness. Coal Transport Model with Mills. Extended Low Load Boiler Operation Kickoff | 12 February 2018 16

Two major parameters which decide the mill capacity and performance are the hardness of coal and the total moisture level in coal. The mill outlet temperature of coalair mixture is maintained between 65 to 90 degree centigrade in the case of low and medium volatile coal. In the case of high volatile coal while the lower limit generally remains as 65 degree centigrade, the upper limit is

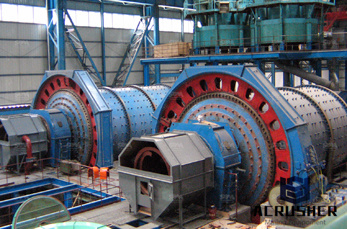

TEMPERATURE DETECTION MILL COAL FEED IR BURNERS CLASSIFIER Figure 5 Ball Mills Suggestions for Enhanced Fire Detection on Double Ended Ball Mills The ball mill is a slow speed mill and has two primary areas where coal pockets can exist and create fires: the inlet/ outlet

The mill outlet temperature has a major impact on the boiler performance levels. The mill outlet temperature directly impacts the dry gas loss in boiler which is a major loss. This depends on the moisture level in coal, the higher the moisture level the quantity of hot

coal mill outlet temperature Shanghai Xuanshi Machinery . coal mill outlet temperature. Nowadays, the XSM stone crusher The mill outlet temperature directly impacts the dry gas loss in boiler, which is a major loss and in turn a loss of boiler performance and efficiency.

Coal Moisture: The degree of drying, and therefore the required mill outlet temperature (from 6580 0 C) will depend upon the type of coal ground. Some residual moisture in fine coal is recommended (Graph below) to minimize the potential of spontaneous ignition of fine coal, which will again vary for different coal types as below:

#0183;#32;Request PDF | Modeling and outlet temperature control of coal mill using Model Predictive Controller | Coal mills are used to grind and dry the raw coal

Milling Coal Temperature. Effects of Mill Performance on Unburnt Carbon in Coal . While renewable energy has undergone wide and rapid deployment, coal is still expected to be the main source of fuel for producing base load power in the near future. Obter pre#231;o. Alan roberts raymond mill.

Mill Inerting and Pulverizer/Mill Explosion . Typical temperature inside the mill with Coal Moisture of 3% Less Moisture = Lower Mill Inlet Temperatures despite the Higher Outlet hot mill inlet temperatures are required to: #167; Dry coal #167; Achieve mill outlet

Air flow distribution at the mill throat, as well as inside the mill, significantly influences the mill performance in terms of separation, drying, coal/air flow uniformity at the mill outlet

Boiler Performance and Mill Outlet Temperature. The mill outlet temperature has a major impact on the boiler performance levels The mill outlet temperature directly impacts the dry gas loss in boiler which is a major loss This depends on the moisture level in coal, the higher the moisture level the quantity of hot air required in mill for the same mill load is higher

Pulverized coal fired boilers the total losses account to about 12 to 14 %. Roughly 50% of the losses can be tuned to the optimum and the other 50 % is governed by fuel properties like hydrogen in fuel, moisture in fuel and ambient air conditions. The main two losses in boiler that can be tuned by operator are carbon loss and dry gas loss. There are a few minor losses in boiler which can also

Objective. The outlet temperature of the coal mill is maintained at desired point so that the coal delivered from the mill is completely dry and achieves the desired temperature. Also, in case of high temperature at the mill outlet, cold air is blown in to reduce the risk of fire.

Dec 01, 2017#0183;#32;After mill outlet temperature change. Following the outlet temperature increase, the fuel line air balance was much more uniform, with most

Coal Supply Coal Crusher Mill Coal Silos Boiler Air Heater Stack ID Fan FD Fan Turbine Generator Peak Temperature ~3500 #176;F Local near burning coal particles Furnace Exit Gas Temperature (FEGT) ~2500 #176;F Economizer Outlet Temperature ~700 #176;F Air Heater Outlet Temperature ~350 #176;F Increasing combustion air preheat 100 #176;F increases peak flame

May 01, 2010#0183;#32;Commercial CFD software, Fluent version was used for the simulation presented in this study. Mill operating conditions were set as shown in the Table coal particles were injected from the grinding table with a particle size distribution calculated from the data shown in Table grinding table and roller wheels were set to rotate at a speed of 20 rpm.

Coal Moisture: The degree of drying, and therefore the required mill outlet temperature (from 6580 0 C) will depend upon the type of coal ground. Some residual moisture in fine coal is recommended (Graph below) to minimize the potential of spontaneous ignition of

coal mill outlet temperature XUANSHI. Boiler Performance and Mill Outlet Temperature. Two major parameters which decide the mill capacity and performance are the hardness of coal

Properties of Coal Coal properties are evaluated by different methods. The most commonly used methods are Proximate and Ultimate analysis of the coal. Proximate analysis gives the Moisture, Ash and Volatile matter, while the Fixed Carbon is found by difference. Ultimate Analysis gives the elemental composition of the coal. Other methods like Macarel analysis is also used

Coal Mill an overview | ScienceDirect Topics. The outlet temperature of the coal mill is maintained at desired point so that the coal delivered from the mill is completely dry and achieves the desired temperature. Also, in case of high temperature at the mill outlet, cold air

WhatsApp)

WhatsApp)