what is grinding process of mineral

Mill (grinding) Wikipedia, the free encyclopedia. Rod mills are less common than ball mills for grinding minerals. The rods used and can be used after ball mills in a grinding process.

WhatsApp)

WhatsApp)

Mill (grinding) Wikipedia, the free encyclopedia. Rod mills are less common than ball mills for grinding minerals. The rods used and can be used after ball mills in a grinding process.

In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores. Mineral processing involves two major categories of processing.

Grinding equipment is one of the important equipment used before mineral processing operation. The particle size of ore is reduced by the impact and grinding of steel ball,steel bar, gravel and other media.

Sepro Mineral Systems Corp. also provides engineering and process design services while continuing to advance its machine technology through research and development. Proprietary technology produced by Sepro includes grinding mills, ore scrubbers, vibrating screens, centrifugal gravity concentrators, agglomeration drums, and dense media separators.

Pedogenesis (from the Greek pedo, or pedon, meaning ''soil, earth,'' and genesis, meaning ''origin, birth'') (also termed soil development, soil evolution, soil formation, and soil genesis) is the process of soil formation as regulated by the effects of place, environment, and history. Biogeochemical processes act to both create and destroy order within soils.

Former Project Manager, Flotation Department, FIA, Freiberg. See Article History. Alternative Titles: mineral dressing, ore dressing. Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of

grinding process mineral processing Blog Crushing is a dry process whereas grinding is generally performed wet and mineral processing grinding Check price. design of minerals dry grinding process villasovaggioit. Rawmill Wikipedia design of minerals dry grinding process Mineral Processing In this brief we will concentrate on mineral

Limestone is a type of carbonate sedimentary is composed mostly of the minerals calcite and aragonite, which are different crystal forms of calcium carbonate (CaCO 3).A closely related rock is dolomite, which contains a high percentage of the mineral dolomite, CaMg(CO 3) old USGS publications, dolomite was referred to as magnesian limestone, a term now reserved for magnesium

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflective surface, the process can also involve roughening as in satin, matte or beaded finishes. In short, the ceramics which are used to cut, grind and polish other softer

A method of grinding a mineralcontaining ore, which includes grinding the mineralcontaining ore in a primary milling process and thereafter fine grinding the mineralcontaining

Grinding is the process of creating grinds. It involves removing significant portions of material from a blade, which distinguishes it from honing and are ground during their initial sharpening or after having been sufficiently damaged, such as by breaking a tip, chipping, or extensive corrosion.

Mineral processing WikipediaOverviewUnit operationsHistoryOther processnferencesSee alsoNotesSourcesMineral processing can involve four general types of uni Mineral Grinding Process Wikipedia 27 Division, mirpur12, pallbi.

In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores. Mineral processing involves two major categories of processing.

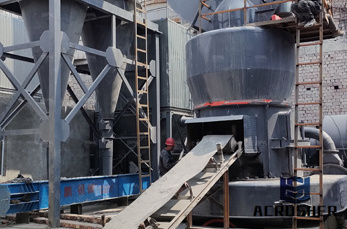

Mineral grinding process general includes three stages, the raw mineral crushing process, mineral mill process and final mineral powder collecting process. 1. Why we need to crush raw material. According to our statistics, 90% customers raw materials are bigger than the max. feeding size of grinding mill. In this case, we will use one small model jaw crusher or one PC hammer crusher crush raw mineral firstly.

Former Project Manager, Flotation Department, FIA, Freiberg. See Article History. Alternative Titles: mineral dressing, ore dressing. Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

Gypsum and calcium carbonate are relatively soft minerals, and rapidly grind to ultrafine particles. Grinding aids are typically chemicals added at a rate of % that coat the newly formed surfaces of broken mineral particles and prevent reagglomeration. They include 1,2propanediol, acetic acid, triethanolamine and lignosulfonates.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand, working animal, wind or water. In modern era, they are usually powered by electricity. The grinding of solid

Grinding Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous. The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles

mineral grinding process wikipedia . Second Hand Concrete Batching Plants For Sale In Malaysia. Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated,

A raw mill is the equipment used to grind raw materials into quot;rawmixquot; during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry of the finished cement, and has a large effect upon the efficiency of the whole manufacturing process. A medium

WhatsApp)

WhatsApp)