Eagle Mine celebrates delivery of first load of ore from

Excavation of Lundin Mining''s Eagle East began Monday, with employees celebrating the first load of ore being brought to the Humboldt Mill. The delivery of ore from Eagle East to the

WhatsApp)

WhatsApp)

Excavation of Lundin Mining''s Eagle East began Monday, with employees celebrating the first load of ore being brought to the Humboldt Mill. The delivery of ore from Eagle East to the

news; workers blocks delivery of ore to the mill agm. july 4, 2019. 0

Risks Involved In Delivery Of The Ore To The Mill . 202057Fortune Minerals Provides NICO Project Update. a mill throughput rate of 4,650 tonnes of ore per day, and processing of metal concentrates at a hydrometallurgical refinery in southern Canada.

traditional marathi wedding songs of grind mill risks involved in delivery of the ore to the mill; COMPLIANCE AND OPERATIONAL RISK . Operational risk is defined as the risk of loss resulting from delivery and process monitoring shall reflect the risks involved and the frequency and rating of cement mill electric drives, rv park

The ORE MILL bar amp; grille logo was designed to capture an image we seek to project. We wanted to include the history of the location in our name and logo. As many of you know the history, it includes a Sawmill dating back to the 1800s and the Ore brook which runs through the property. Take a look at what we''ve been doing!

Iron ore pellets are spheres of typically 616 mm ( in) to be used as raw material for blast typically contain 6472% Fe and various additional material adjusting the chemical composition and the metallurgic properties of the pellets. Typically limestone, dolomite and olivine is added and Bentonite is used as binder.

The raw mix, high grade limestone, sand, and iron ore are fed from their bins to raw mills, called air swept mills, for drying and fine grinding. The raw mill contains two chambers, separated by diaphragm, namely a drying chamber and a grinding chamber.

First ore has been hauled from the Kalgoorlie North gold project, in Western Australia, to gold miner Norton Gold Fields Paddington mill. ASXlisted Excelsior Gold said on Thursday that the

Sotkamo Silver has entered into an agreement with Outotec (Finland) Oy on the delivery of a grinding mill circuit to the Silver Mine project, which is under construction in Central Eastern Finland. The mills will have a capacity of 450,000 tonnes of ore per year in full production.

The geometry of a mill with conical ends is shown in Figure The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm () The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore

THE MILL BUILDING IS IN THE BACKGROUND CENTER RIGHT AND ONE OF THE ORE DELIVERY TRESTLES EXTENDING FROM THE MILL BUILDING TO RIGHT IMAGE EDGE. Standard Gold Mill, East of Bodie Creek, Northeast of Bodie, Bodie, Mono County, CA Photos from Survey HAER CA299

8. second image of the panoramic series looking west from the uphill side of the mill. the ore receiving house and the ore delivery trestle is image right, the mill building and ancillary structure are image center and the town of bodie is image background right. standard gold mill, east of bodie creek, northeast of bodie, bodie, mono county, ca

ORE MILL Bar amp; Grille. 17 Lake Tarleton Road, Warren, New Hampshire

10. detailed view of the east elevation. the upper set of windows provide light for the delivery level. the lower sets of windows provide light to three story space beneath the delivery level and behind the ore storage bins. note the ore deliver trestle at the time the photograph was taken, the modern cement mixer and wheelbarrows were for this

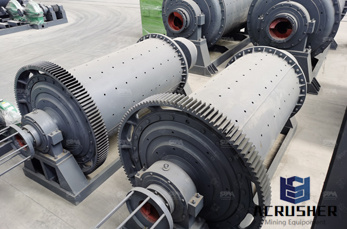

Ball mills are filled up to 40% with steel balls (with 3080 mm diameter), which effectively grind the ore. The material that is to be ground fills the voids between the balls. The tumbling balls capture the particles in ball/ball or ball/liner events and load them to the point of fracture.

The US iron and steel industry has paralleled the industry in other countries in technological developments. In the 1800s, the US switched from charcoal to coke in ore smelting, adopted the Bessemer process, and saw the rise of very large integrated steel the 20th century, the US industry successively adopted the open hearth furnace, then the basic oxygen steelmaking process.

About us Founded in 1997, Shandong Xinhai Mining Technology amp; Equipment Inc,under Xinhai is a stockholding high and new technology enterprise to provide

ORE MILL Bar amp; Grille. 886 likes. Serving locallysourced food, craft beer, wine and cocktails

The mills will have a capacity of 450,000 tonnes of ore per year in full production. Outotec which will be responsible for delivery, is a worldleading mining technology company. According to the agreement, both mills in the grinding circuit will be delivered during autumn 2018.

news; workers blocks delivery of ore to the mill agm. july 4, 2019. 0

WhatsApp)

WhatsApp)