(PDF) MECHANICAL COMPORTEMENT OF A CEMENT

rotary cement kiln using artificial neural networks, 30 (2009) . [5] Bernard Gilbert, Alain Regnault, Fours de cimenterie, four rotatif, BE 8845 Editions techniques de ling#233;nieur.

WhatsApp)

WhatsApp)

rotary cement kiln using artificial neural networks, 30 (2009) . [5] Bernard Gilbert, Alain Regnault, Fours de cimenterie, four rotatif, BE 8845 Editions techniques de ling#233;nieur.

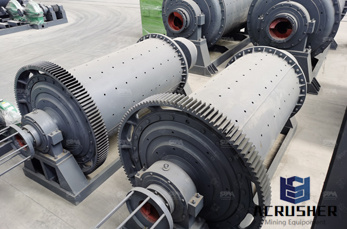

Cement Kiln Capacity Calculation Html. Kiln Capacity Calculation. Cement mill crusher capacity 3 grinding equipment cement mill crusher 3 cement mill crusher is a kind of mechanical equipment which can meet the production requirements of coarse grinding, fine grinding and ultrafine grinding in the field of industrial grinding.

In long wet or high capacity preheater kilns this can exceed 25 GJ per hour per metre squared (GJ/hm2). To measure thermal load you must calculate the thermal input to the kiln through the main burner in GJ per hour. Then calculate the crosssectional area of the kiln inside the refractory lining. Divide one by the other and you have the thermal load.

Kiln and Combustion Calculation Training. Burning zone loading, or Thermal loading. Volumetric loading. Material residence time in kiln. Cooler Loading. By the end of this course, you will be covering more than 25 basic calculations you need on daily basis in cement plant.

Calculation Of Thermal Loading In Cement Kiln rotary cement kiln energy usage 278 mineral ore reduction processes in rotary kilns 280 the rotary kiln sl/rn process 280 roasting of titaniferous materials 282 the rotary kiln lightweight aggregate making process 285 lwa raw material characterization 288 lwa feedstock mineralogy 289 lwa thermal

Modelling and optimization of a rotary kiln direct reduction process 53 Figure 2. Comparison of fill level calculation with experimental data. The method allows for the treatment of a number of geometrical parameters related to the kiln, including: Variations in kiln

Calculation Of Thermal Loading In Cement Kiln. Cement kiln performance calculations by vvijaybhan in types instruction manuals and cement kiln performance calculations thermal loading or burning zone loading formula1 tl gcal2 f ncv a formula2 p h a 3 coal flames for cement kilns uploaded by vvijaybhan fan flow calculation uploaded by.

PATEFFECT ON THERMAL EFFICIENCY FOR CEMENT KILNS Unit Potential savings with marginal investment (Kcal/kg clinker) Clinker Productio n (LTPA) PAT Effect (TOE/annum) Equivalent coal saving per annum (Tonnes ) K1 30 6633 13266 K2 25 12045 K3 20

calculation of thermal loading in cement kiln. calculation of thermal loading in cement kiln frequently asked questions temperature range a pyrometer is a noncontacting device that intercepts and measures thermal radiations. read now; calculation of thermal loading in

During cement production process, part of the fuel can be burned in preheater, so it is necessary to supply additional air (tertiary air), which should be taken from the clinker cooler [1].

#0183;#32;IMPOTANT PARAMETERS KILN SPECIFIC VOLUME LOADING = TPD/ m3 or Specific Kiln capacity ~ t / m3 at Kiln circumferential speed = 50 cm / sec KILN SPECIFIC THERMAL LOADING = Kcal / Specific Kiln thermal loading Qp = x 10 ^ 6 x D Kcal / m2. hr Qp should not exceed x 10^6 Kcal/m^ COOLER SPECIFIC LOADING or Specific Cooler Capacity = TPD/

The Cement Kiln. The original rotary cement kilns were called 39wet process39 kilns. In their basic form they were relatively simple compared with modern developments. The raw meal was supplied at ambient temperature in the form of a slurry. A wet process kiln

Introduction of Cement rotary kiln Cement rotary kiln is the main equipment for dry and wet production of cement calculation of thermal loading in cement kiln MTM Crusher . Home gt; Application gt; calculation of thermal loading in cement kiln. 21 Oct 2009 In this paper the stresses in the riding ring of cement rotary kiln

Rotary kiln calculations, Burning zone load, volumetric loading, Radiation Losses Pyro Calculations. Size Calculations Degree of filling DF% Burning zone/Thermal loading TL Volumetric loading VL Material residence time in kiln RTK. Go To Online Calculators. Cooler Loading CL Clinker residence time in cooler cement

Kiln Capacity Calculation False Air Calculation Heat . Rotary kiln calculations Burning zone load volumetric loading Radiation Losses Convection Losses Flame momentum Burner tip velocity Calorific value Burning zoneThermal loading TL Volumetric loading VL Material residence time in kiln RTK cement . Get Details; Applied Thermal Engineering

Calculation Of Thermal Loading In Cement Kiln. 201994thermal energy equipment furnaces and refractories withstand load and abrasive forces conserve heat have low coefficient of thermal expansion should not contaminate the material with which it comes into contact table 1 compares the thermal properties of typical high density and low density refractory materialsable 1.

WhatsApp)

WhatsApp)