4 Beneficiation Processes to Obtain Aluminum from Bauxite

Bayer process Wikipedia

WhatsApp)

WhatsApp)

Bayer process Wikipedia

Aluminum is the most abundant metal in the earths crust and is a constituent of many minerals. However, the material which is highest in aluminum and most free from objectionable impurities is bauxite which, therefore, is practically the only source of the metal under present processes. Bauxite is the general name given to the hydrated oxides of aluminum. It contains varying amounts of

Feb 27, 2019#0183;#32;The material that is discharged from the mill is called slurry. Digestion: The slurry is pumped to a digester where the chemical reaction to dissolve the alumina takes place. A hot caustic soda solution is used to dissolve the aluminumbearing minerals in the bauxite to form a sodium aluminate supersaturated solution.

Typical deposits range in thickness from 3 to 15 meters. However, there have been some deposits that can reach 200 to 300 meters in depth. The typical processes involved in the mining bauxite are as follows: Clearing of vegetation and timber using scrapers and bulldozers.

The Bayer Process. The Bayer Process, which is used by about 80 active plants worldwide, is the primary method of producing aluminum from bauxite. Bauxite ore is dissolved in sodium hydroxide, or lye, at a high temperature and pressure. Then, the alumina and bauxite ores are separated by washing out the waste (red muds or sands) from the alumina.

Once the bauxite is loosened into manageable pieces it is generally loaded into trucks, railroad cars or conveyors and transported to crushing and washing plants or to stockpiles, before being shipped to alumina refineries, which are generally located close to bauxite mines. Unlike the base metal ores, bauxite does not require complex processing because most of the bauxite mined is of an

Al2O3 + 2 NaOH gt; 2 NaAlO2 + H2O. Once this reaction has occurred, bauxite residue can be separated from the solution through a sedimentation process. The alumina can then be crystallized from the solution via a precipitation process which carries out the following reaction: Al

The Process of Mining Bauxite Dajcor Aluminum Ltd. Feb 27, 2019#183; The Process of Mining Bauxite. by Dajcor Aluminum. Bauxite is a mineral that contains varying amounts of combined water and several impurities of which ferric oxide and silica are usually predominant. It is found in a belt around the equator and is generally extracted by open

Jul 23, 2020#0183;#32;We can get aluminum from bauxite beneficiation process, and the elements of residues in the process are iron oxide (10 30%), titanium dioxide (2 15%), silicon oxide (5 20%), and insoluble oxidation aluminum (020%).. These elements are difficult to completely eradicate from the residue, so it has caused a series of ecological problems.

The first step in the commercial production of aluminum is the separation of aluminum oxide from the iron oxide in bauxite. This is accomplished using a technique developed by Karl Joseph Bayer, an Austrian chemist, in 1888. In the Bayer process, bauxite is mixed with caustic soda, or sodium hydroxide, and heated under pressure. The sodium hydroxide dissolves the aluminum oxide, forming sodium aluminate.

Extraction and refining. The production of aluminum from bauxite is a twostep process: refining bauxite to obtain alumina and smelting alumina to produce aluminum. Bauxite contains a number of impurities, including iron oxide, silica, and titania.

Bauxite Mining. Scrapers and small excavators are used to remove the remaining overburden and expose the caprock. Depending on the depth of the caprock, it can be broken by blasting, or simply removed with scrapers and excavators. The bauxite is then mined using excavators or loaders to load the bauxite onto haul trucks and transported to the crusher.

Bauxite is collected from the ground in an openpit mining operation. It doesnt sit very deeply in the earths crust, so some energy can be saved on drilling. However, to recover all the aluminum in an area, swaths of land must be bulldozed to reveal the dirt and ore underneath. Once collected, the bauxite ore has to be refined. Facilities use chemical processes to weed out other compounds like silica and iron

Quick Read. Alumina is the common name given to aluminum oxide (Al 2 O 3 ). Alumina is produced from bauxite, an ore that is mined from topsoil in various tropical and subtropical regions. The Bayer process, discovered in 1887, is the primary process by which alumina is extracted from bauxite. To produce pure aluminum, alumina is smelted using the HallH#233;roult electrolytic process.

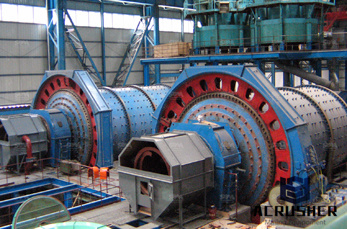

Alumina is used for the production of aluminium metal, through the HallH#233;roult electrochemical smelting process. 1. MillingThe bauxite is washed and crushed, reducing the particle size and increasing the available surface area for... 2. DesilicationBauxites that have high levels of silica (SiO 2)

Jul 29, 2020#0183;#32;4 Beneficiation Processes to Obtain Aluminum from Bauxite Orewashing process for bauxite. Ore washing is the simplest and most effective method to improve the bauxite... Flotation separation methods. It is mainly used to separate diaspore

Enhance base metal mining efficiency with analytical solutions to reduce wasted spend, improve base metal grading, separation and refining. Our portable and flexible elemental analysers are perfectly suitable to monitor impurity levels of bauxite and process liquors

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef, the most important ore of aluminium, contains only 3060% aluminium oxide (Al 2 O 3), the rest being a

WhatsApp)

WhatsApp)