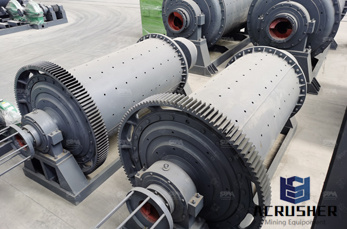

Gold Ore Ball Mills and Floatation Cells, Mongolia YouTube

#0183;#32;These Mongolian ASM formed a hard rock quartz ore mining coop and built this ball mill and and flotation cell circuit for gold recovery.

WhatsApp)

WhatsApp)

#0183;#32;These Mongolian ASM formed a hard rock quartz ore mining coop and built this ball mill and and flotation cell circuit for gold recovery.

5 cells RESULTS 2% improved gold recovery Implementation of SkimAir to all other process lines. provinces, Olimpiada is Polyus largest operation. The mine began production in 1996 and currently accounts for over a half of the companys total gold flotation cell in 2016. The cell was installed in the

#0183;#32;Most methods of waterbased gold extraction are dependent on golds lack of buoyancy to work. However, froth flotation uses a different property of gold to separate it from ore. Froth flotation is a method for separating hydrophobic materials (which will not mix with water) from hydrophilic materials (which readily mix with water).

And what''s more, flotation concentrator can be used for sorting the metal material including copper, lead and gold. And flotation cell is also being called flotation separator, flotation machine and flotationcell. AfterSales Service * Training how to instal the machine, training how to use the machine.

Newcrests Telfer gold mine, located in the South Western area of the Great Sandy Desert in the Paterson Province of Western Australia, processes low grade coppergold ores from open pit and underground sources in two parallel processing trains. The copper flotation

range of cell sizes on the market, from 5 to 630 m3. Our cells provide superior performance across all duties in rougher, scavenger, and cleaner circuits. Based on indepth test work, we can design a tailormade flotation circuit for your plant that will deliver optimized cell volume, froth carry rate, and residence time. OUTOTEC FLOTATION

Table of ContentsMechanical Fine Gold Flotation CellAir Sparged Hydrocyclone Gold Flotation Column In view of the tendency of fine gold recover by floating and the dominance of heavy minerals, the prospects for flotation were worthy of reinvestigation, particularly with the new tools of the air sparged hydrocyclone (ASH) and the flotation column. Although gold readily and naturally forms a

Froth flotation is a process for selectively separating hydrophobic materials from is used in mineral processing, paper recycling and wastewater treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century.

Though the gold recovery methods previously discussed usually catch the coarser particles of sulphides in the ore and thus indirectly recover some of the gold associated with these and other heavy minerals, they are not primarily designed for sulphide recovery. Where a high sulphide recovery is demanded, flotation methods are now in general use, but in the days before flotation was known, a

Flotation Cell Gold Ore Flotation Tank Price Copper Ore Flotation Cell Manufacturer Flotation Separator Machine For Mining . US / Piece Jiangxi Province County Mining Machinery Factory (5) % quot; Fast delivery quot; (2)

This cell is universally accepted as a standard cell for laboratory flotation experiments. In Figure, a schematic of the Denver cell equipped with two power transducers is shown operating at 20 kHz. The ultrasonic transducers are in acoustic contact with the body of the flotation cell but are not immersed in the same cell.

Gold Flotation Production Line. Process Introduction. The flotation meth od is a widel y used technique for the recovery of gold from goldcontaining copper ores, base metal ores, coppernickel ores, platinum group ores and many other ores where other processes are not applicable. Flotation is also used for the removal of interfering impurities before hydrometallurgical treatment, for

#0183;#32;BGRIMMMAT is the main supplier of technologies and equipment for the mining industries in China.

WhatsApp)

WhatsApp)