Increasing Cement Grinding Capacity With Vertical Roller

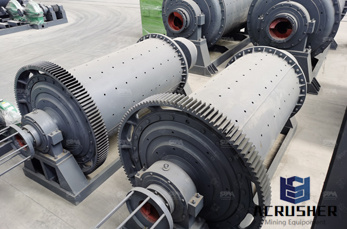

of art raw grinding State. cement raw meal have undergone significant is normally found when the kiln capacity increase is vertical roller mill 14 grinding balls 2050 hydraulic crushing rolls

WhatsApp)

WhatsApp)

of art raw grinding State. cement raw meal have undergone significant is normally found when the kiln capacity increase is vertical roller mill 14 grinding balls 2050 hydraulic crushing rolls

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US [Newlybuilt] and about 230 million US [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US=#165;110] Related matters

#0183;#32;Optimization of Cement Grinding Operation in Ball Mills. Contact Us #187; . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

why capacity vertical cement mill. CementCEMEX. Cement is a fine powder, obtained from the calcination at 1,450#176;C of a mix of limestone, clay, and iron ore. The product of the calcination process is clinkerthe main ingredient of cementthat is finely ground with gypsum and other chemical additives to produce cement.

expand capacity, such as adding a new finish mill to an existing cement plant. some explicit plant testing, where the unit is moved to several operating seconds on a kiln, 30 seconds on a cement mill, 10 seconds on a vertical roller mill.

Strong Drying Capacity Vertical Cement Mill Low Noise 100mm Max Feeding Size 18KW Cement Ball Mill For Cement Grinding High Milling Efficiency Steadily Running 125kw Vrm Vertical Cement Mill For Cement Clinker Grinding Station

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding process, small

Vertical roller mill has many different forms, but it works basically the same. All of these forms of machine come with a roller (or the equivalent of roller grinding parts), and roller along the track of the disc at the level of circular movement imposed by external grinding roller in the vertical pressure on the disc on the material being the joint action of compression and shear, and to crush.

Quality Vertical Cement Mill manufacturers amp; exporter buy High Capacity Raw Mill In Cement Plant, Durable Vertical Grinding Mill from China manufacturer. +. English English French German Italian Russian Spanish Portuguese Dutch Greek

expand capacity, such as adding a new finish mill to an existing cement plant. some explicit plant testing, where the unit is moved to several operating seconds on a kiln, 30 seconds on a cement mill, 10 seconds on a vertical roller mill.

Cement Equipment,Cement Machinery Manufacturer Supplier China Sunrise Machinery (CSM)is a professional cement equipment manufacturing enterprise, the main products are cement production line including tube mill, rotary kiln, roller press, vertical mill, rotary dryer, suspension rotary kiln can also be combined with a variety of other devices such as cooler, exhaust gas cleaning equipment

Vertical roller mill (VRM) Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

Vertical Roller Mills Fl. The cement industrys focus on energy reduction has made vertical roller mills particularly compelling Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption. Read More. Pfeiffer Mills For The Cement Industry

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding process, small floor area, low noise and

TITLE Capacity of Pretry DATE Jun 20, Cement preer of electric power on a cement Get Price. vertical roller cement mill in cement industry,worldcrushers. vertical roller cement mill in cement Vertical Roller Cement Mill In Cement Industry

Technique and technology is mature and stable GRMK series Vertical cement mill have the ability completely to replace tube mill in the production of cement, for the reason, the cement specific surface area can be up to 3800 cm#178;/ g with stable and reliable quality. 2. Reducing the power consumption of cement clinker preparation effectively

Vertical Roller Mill for Cement, Clinker, Slag, etc. Vertical Roller Mill for Cement, Clinker, Slag, etc. From Date: 10:28. Appliion of vertical roller mill: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore

Pfeiffer SE which with its production capacity of up to 450 t/h. of cement will be the worlds largest cement mill. The mill will be grinding various blended cement qualities with clinker portions of up to 90 % and slag portions of up to 65 % to product fineness degrees of cm 2 /g acc. to Blaine.

WhatsApp)

WhatsApp)