(PDF) Optimisation of Drill and Blast Parameters Using

Blasting is the most productive excavation method in hard rock mining. In quarries, to remove the mother rock from insitu and crush into the desired size is realized by bench blasting method.

WhatsApp)

WhatsApp)

Blasting is the most productive excavation method in hard rock mining. In quarries, to remove the mother rock from insitu and crush into the desired size is realized by bench blasting method.

big bench blasting in mining operations crusher, bhp mining area c production mining machinery mining crusher crusher machineour site is about the mining . Get Price. mining inglese italiano wordreference. gold mining will have a big impact on political stability in the region. bench cage claim coal seam culm damp face fire .

Blasting Mining Operation Nevada big bench blasting in mining operations winkelsinwijsheidnl. Bench blasting Bench blasting using propellant cartridges is a practical option in civil work and tunnelling mining operations where environmental issues

In mining operations, blasting has become a routine burst at the bottom. the rest of the burden m ay come as a big block. Bench blasting is a common blast technique m ost often used for

big bench blasting in mining operations. konsentrat tembaga pabrik pengolan ubara di #187; big bench blasting in mining operations #187; mining iron ore use hydraulic cone south africa jaw crusher in . Read More. Chat Now Openpit mining Wikipedia. Mining can be conducted on more than one bench

#0183;#32;In large surface mining operations, drilling and blasting activities constitute more than 15% of the total costs. In order to optimize performance and minimize costs, a thorough knowledge of drill and blast operations is, therefore, extremely important. In this unique reference volume, rotary blasthole drilling and surface blasting, as applied in large surface mines, are comprehensively

AEISG Code of Good Practice, Blast Guarding in an Open Cut Mining Environment. Note: The potential for undesired blasting outcomes at the time of firing needs to be considered whilst carrying out onbench

It enhances good fragmentation, optimum The data to be collected are classified into two groups, namely parameters parameters PARAMETERS Burden Spacing Hole diameter Hole depth Subdrill PARAMETERS Stemming height Stemming material Powder factor, K NUMBER AVERA AVERA HOLE AVERA AVERAG AVERA OF GE GE DIAMET GE E GE BLASTIN BURDE SPACIN ER HOLE BENCH

Large diameter holes give a better drilling economy but may at a later stage of the preparation of the rock lead to added costs. In largescale mining operations, it is possible to use blast hole diameters of up to 400 mm while in a smallscale construction operation a blast hole diameter of

(PDF) ROCK BLASTING FOR MINING ResearchGate

Mine Blasting amp; Explosives Technology, and Safety Regulations. Blasting is used in both open pit and underground mining traditional blasting...Bench blasting is abig companies that offer blasting...

Its important to conduct blasting operations within a framework that considers multiple blast outcomes: TRENDS IN FRAGMENTATION A global trend is emerging in which mining companies are subcontracting out the total blasting services (including drilling). Some companies have even subcontracted all work functions at the mine and processing plant.

Bench Preparation: Easily Avoid Hazards. One of the first steps in an optimized drill and blast workflow is the bench preparation. Apart from achieving optimal blast results, this also refers especially to safety, which should be an essential key practice in the forefront of every blasting engineers mind.

blasting system that is specifically designed for use in underground mining operations. BlastWeb allows reliable remote initiation of development and production blasting from a safe and controlled location underground or on the surface. The blast areas can be completely evacuated as noone is required to be underground for the blasting.

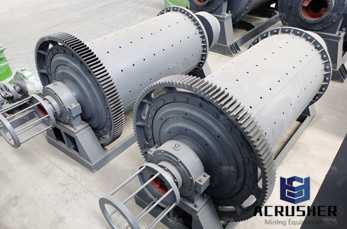

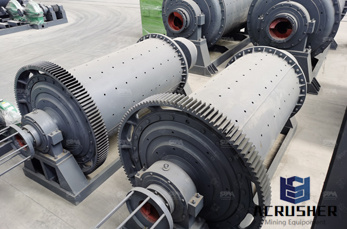

big bench blasting in mining operations SBM Ball Mill. SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the big bench blasting in mining operations, sand amp; gravel, quarry, mining, construction

big bench blasting in mining operations Some other researchers made attempts to optimize drilling and blasting operations from the technical point of view Sontamino and Drebenstedt addressed a dynamic model for a bench blasting design Bowa introduced a practical method in an open pit mine to optimize blasting design parameters such as bench height drill hole diameter spacing

#0183;#32;In mining operations, blasting has become a routine burst at the bottom. the rest of the burden m ay come as a big block. Bench blasting is a common blast technique m ost often used for

Big Bench Blasting In Mining Operations Aug 28, Blasting is heavily regulated and watched by federal, state and local agencies. In terms of processing, blasting is the critical first step in the rockfragmentation process. Maximum profitability depends largely on an optimized blast.

WhatsApp)

WhatsApp)