ore dressing ore wet mill and ball mill

ore dressing ore wet mill and ball mill. Home; stone crusher zone in himachal pradeshl; ore dressing ore wet mill and ball mill

WhatsApp)

WhatsApp)

ore dressing ore wet mill and ball mill. Home; stone crusher zone in himachal pradeshl; ore dressing ore wet mill and ball mill

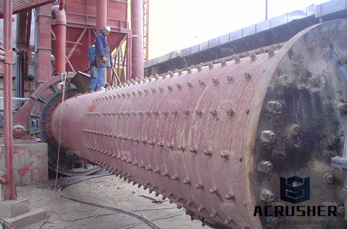

Ball MillBall mill is ore dressing equipment, mainly used for crushing bulk ore materials into ore pulp, for further separating operations. Spiral ClassifierSpiral separator is large grading equipment. This machine classifies materials according to the different sizes and proportions of solid particles. Magnetic SeparatorMagnetic separator is common used magnetic separator machine, especially in the

Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration Ore Grinding Mill THEORY BALL AND TUBE MILLS the California stamp mill, a complete description of which can be found in Richard and Lockes Text Book of Ore Dressing

Ore Dressing Ore Ball Mill Mill Center Make Ore Make Ore Suppliers and Manufacturers at fine ball mill for copper ore making machine in ore dressing fine ball mill for copper ore making machine in ore dressing offers 15085 make ore products About 1 of these are iron ore 1 are copper ore and 1 are seals A wide variety of make ore options are available to Contact Customer Service.

Ball mill wikipediathe ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cemen ore

Wet rod mill is mainly used for coarse grinding. It is configured for fine and coarse grinding in the first stage opencircuit grinding, especially suitable for brittle ore is a high technological enterprise that integrated research, manufacture, sales and service . The company has multiple subsidiaries such as Mineral Processing Research Institute...

Highpressure Ball Pr... READ MOREgt;gt; GRINDING MILL Overflow Ball Mill Grid Ball Mill Cement Mill Rod Mill Raw Mill Autogenous Mill Airswept Coal Mill READ MOREgt;gt; ORE DRESSING EQUIPMENT LL Series Centrifuge Flotation machine Shaking table Magnetic separator Ore thickener Spiral chute Spiral classifier Wet pan mill Vacuum disk filter Jig machine

offers 1,105 ore dressing equipment ball mill products. About 21% of these are mine mill, 1% are grinding equipment. A wide variety of ore dressing equipment ball mill options are available to you, such as ac motor, dc motor, and stepper motor.

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle, which greatly reduces the cost of the ore dressing

Mill, Ball Mill, Grinding Mill manufacturer / supplier in China, offering Ball Mill for Gold Ore Dressing Production Line (Diamter1200mmX3000mm), Mantle and Concave Wearing Parts for Cone Crusher of , , , and , Pfl Vertical Compound Sand Making Machine and so

Ball Mill Ore Dressing . Grid ball mill is widely used in smashing all kinds of ores and other materials ore dressing and national economic departments like building and chemical industries etc the size of ore shall not exceed 65mm and the best feed size is under 6mm the effect in this job is

Home gt; Products center gt; Ore dressing machine gt; Ceramic Ball Mill Ceramic Ball Mill This new Ceramic ball mill is mainly used for mixing, grinding and finely grinding the materials, and the fineness of the final products is even and the electricity consumption is low.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis.

The cone ball mill is a key machine that smashes the materials having been crushed, and is widely used in industries like cement, silicate products, new 52555 building materials, refractory materials, fertilizer, black and nonferrous metal ore dressing and glass ceramics production.

SMALL Batch BALL MILL. This mill may be used for batch or intermittent grinding, or mixing of dry or wet materials in the ore dressing industry, metallurgical, chemical, ceramic, or paint industries. The material is ground and mixed in one operation by rotating it together with balls, or pebbles in a hermetically sealed cylinder.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ferrous and nonferrous metals.

HomeProducts center gt; Ore Dressing Machine gt; Ball Mill print. Ball Mill. Production Capacity:: /h Feeding size: 25mm Material handling: cement, silicate, fertilizer, ferrous metal and nonferrous metal, glass ceramics, etc. Leave Message. Products Discounted Prices. Features

Ball Mill. Ball mill is the ore processing machine for grinding the broken material during the ore processing. Details; Wheel Mobile Crusher. The wheel mobile crusher is the crushing equipment driving by wheel and integrated operation. Details; Raymond Mill. Raymond mill is a kind of grinding equipment, the material that after deal with can

Application of Ball Mill to Tanzania Gold Ore Dressing Plant. 03. Jun 2019. Aileen . Commonly used gold ore beneficiation mainly includes classifiers, ball mills, flotation machines/magnetic separators, mixer, and concentrators. Recently, Mining Machinery Co., Ltd. has contracted the gold mining plant project in Tanzania.

Ball mill is widely used in mining, smelting,road,building material and chemical. It is the key equipment for grinding after the crush mill consists of feeding device, driving assembly, rotating assembly, bearing unit,discharging assembly and foundation is a high technological enterprise that integrated research, manufacture, sales and service .

2. Energysaving grate ball mill adopts groovetype circular lining plate that is instrumental in increasing contact areas of iron balls and ores, which enhances grinding action and ore lifting capacity and decreases energy consumption. 3. Energysaving grate ball mill adopts whole milling house, which makes it easy for construction and

WhatsApp)

WhatsApp)